PD6870 Explosion-Proof Loop-Powered Process Meter

Instruction Manual

7

Installation

For Installation in USA:

The PD6870 must be in-

stalled in accordance with the National Electrical

Code (NEC) NFPA 70.

For Installation in Canada:

The PD6870 must be in-

stalled in accordance with the Canadian Electrical

Code CSA 22.1. All input circuits must be derived

from a CSA approved Class 2 source.

For European Community:

The PD6870 must be in-

stalled in accordance with the ATEX directive

2014/34/EU and the product certificate Sira

10ATEX1116X.

•

Installation and service should be performed only

by trained service personnel. Service requiring

replacement of internal components must be

performed at the factory.

•

Disconnect from supply before opening

enclosure. Keep cover tight while circuits are

alive. Conduit seals must be installed within

18" (450mm) of the enclosure.

All controls and wiring connections are located on the

display module that is accessed by removing the en-

closure cover. The controls can be accessed without

removing the display module. The wiring connections

can be accessed by removing the display module

which is secured to the enclosure by two captive

screws.

Unpacking

Remove the meter from box. Inspect the packaging

and contents for damage. Report damages, if any, to

the carrier.

If any part is missing or the meter malfunctions,

please contact your supplier or the factory for

assistance.

Pre-Installed Conduit Plug

The PD6870 is supplied with one pre-installed conduit

plug for installations that do not require the use of

both conduit entries. The conduit/stopping plug in-

cludes an internal hexagonal socket recess for

removal. The conduit plug and its factory installation

are included in all hazardous area approvals of this

product.

•

In hazardous areas, conduit and conduit/stopping

plugs require the application of non-setting

(solvent free) thread sealant. It is critical that all

relevant hazardous area guidelines be followed for

the installation or replacement of conduit or plugs.

Mounting

The PD6870 has two slotted mounting flanges that

may be used for pipe mounting or wall mounting.

Alternatively, the unit may be supported by the

conduit using the conduit holes provided.

Refer to

•

Do not attempt to loosen or remove flange bolts

while the meter is in service.

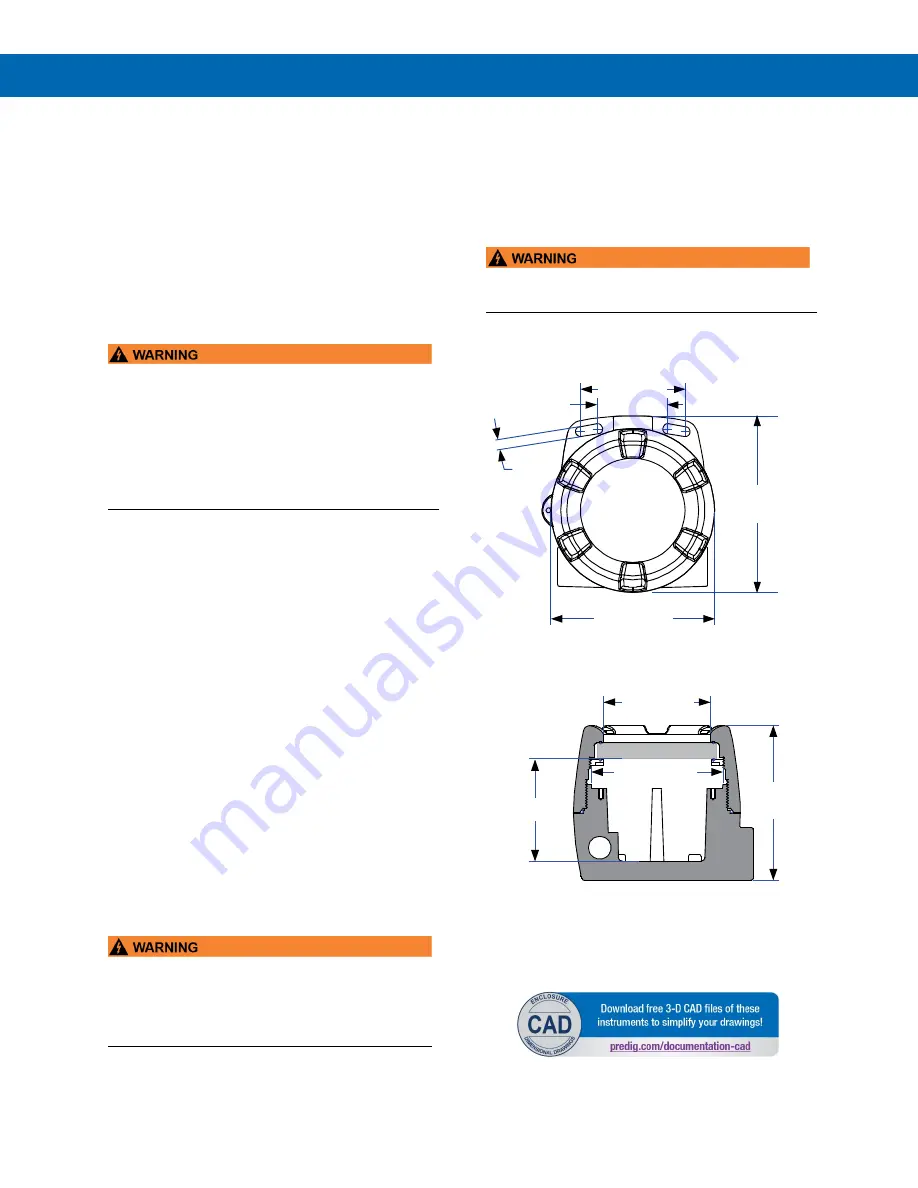

Dimensions

All units: inches (mm)

Figure 1. Enclosure Dimensions – Front View

Figure 2. Enclosure Dimensions –

Side Cross Section View

Note:

The supplied conduit plug may extend up to 0.6

in [15 mm] from the conduit opening when installed.

3.35 (85.1)

2.25 (57.1)

5.25 (133.4)

(143.5)

5.65

(8.2)

0.32

3.35 (85.0)

4.15 (105.5)

3.22 (81.9)

(123.5)

4.86