37

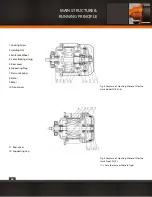

Fig. 5 Constructional Drawing for Lifting motor

1. Ring shield

2. Bearing

3. Snap ring

4. Coupling screw

5. Spring washer

6. Front end cap

7. Hole ring

8. Bearing

9. Round wire snap ring

10. Rotor assembly

11. Surface bearing

12. Bearing

13. Shield cap

14. Rivet

15. Nameplate

16. Stator assembly

17. Back end cover

18. Fan brake wheel

19. Lock nut

20. Screw

21. Spring washer

22. Washer

23. Fan cover

24. Screw

25. Spring washerpring washer

STRUCTURAL FEATURES

Summary of Contents for PWMD Series

Page 1: ...1 PWMD and PWMDF SERIES User Manual and Security Warnings...

Page 17: ...17 MAIN STRUCTURE RUNNING PRINCIPLE...

Page 18: ...18 MAIN STRUCTURE RUNNING PRINCIPLE...

Page 19: ...19 MAIN STRUCTURE RUNNING PRINCIPLE...

Page 20: ...20 MAIN STRUCTURE RUNNING PRINCIPLE...

Page 21: ...21 MAIN STRUCTURE RUNNING PRINCIPLE...

Page 22: ...22 MAIN STRUCTURE RUNNING PRINCIPLE...

Page 28: ...28 MAIN STRUCTURE RUNNING PRINCIPLE...

Page 29: ...29 MAIN STRUCTURE RUNNING PRINCIPLE...

Page 33: ...33 PRECAUTION AND TROUBLE SHOOTING...

Page 66: ...66 b PWMD3T24M TECHNICAL SPECIFICATIONS...

Page 67: ...67 c PWMD5T24M TECHNICAL SPECIFICATIONS...

Page 68: ...68 d PWMD10T24M TECHNICAL SPECIFICATIONS...

Page 69: ...69 e PWMD16T24M TECHNICAL SPECIFICATIONS...

Page 70: ...70 f PWMD20T24M TECHNICAL SPECIFICATIONS...

Page 71: ...71 g PWMD25T18M TECHNICAL SPECIFICATIONS...

Page 72: ...72 h PWMD50T12M TECHNICAL SPECIFICATIONS...

Page 73: ...73 i PWMD50T20M TECHNICAL SPECIFICATIONS...

Page 74: ...74 j PWMDF3T24M TECHNICAL SPECIFICATIONS...

Page 75: ...75 k PWMDF5T24M TECHNICAL SPECIFICATIONS...

Page 76: ...76 l PWMDF10T24M TECHNICAL SPECIFICATIONS...

Page 77: ...77 m PWMDF16T24M TECHNICAL SPECIFICATIONS...

Page 78: ...78 n PWMDF20T24M TECHNICAL SPECIFICATIONS...

Page 79: ...79 o PWMDF25T18M TECHNICAL SPECIFICATIONS...

Page 80: ...80 p PWMDF32T18M TECHNICAL SPECIFICATIONS...

Page 81: ...81 q PWMDF50T12M TECHNICAL SPECIFICATIONS...

Page 82: ...82 r PWMDF50T20M TECHNICAL SPECIFICATIONS...

Page 84: ...84...