xxi

Proxess C-Series Service Manual

APPENDIX A: INSTRUCTIONS FOR DOOR AND FRAME PREPARATION OF CYLINDRICAL LOCK

A. CHECKLIST (4 each AA Batteries Included)

Tools for Door Preparation

•

Drill

•

Drill Bits: Ø1” (Ø31/32” for drive in latch), Ø13/16”, Ø3/8”, Ø5/16”

•

Hole Saw: Ø2-

1/8”

•

Phillips Screwdriver, #2

•

Hammer

•

Chisel

Parts List: Each Proxess C-Series lockset includes

•

Exterior lock assembly (include housing, lever and cylinder drive unit)

•

Interior lock assembly

•

Installation Instructions

•

Door Preparation Template

•

Hardware box includes:

-

Electrified lock chassis assembly

-

Interior lever + Steel ring

-

Exterior rose/chassis mounting plate

-

Interior rose/chassis mounting plate

-

Latch bolt with deadlock

-

2 Keys

-

ASA Strike

-

Screw Pack includes:

▪

(SB1) Hager mounting screws M5 x 38mm x4pcs

▪

(SB2) Flat head tapping screws #8x3/4" x2pcs

▪

(SB3) Flat head tapping screws #12-24 x 18mm x2pcs

▪

(SB4) Lever release tool

▪

(SB5) Hager mounting screws M6 x 10mm x2pcs (optional)

▪

(SB6) Trox wrench

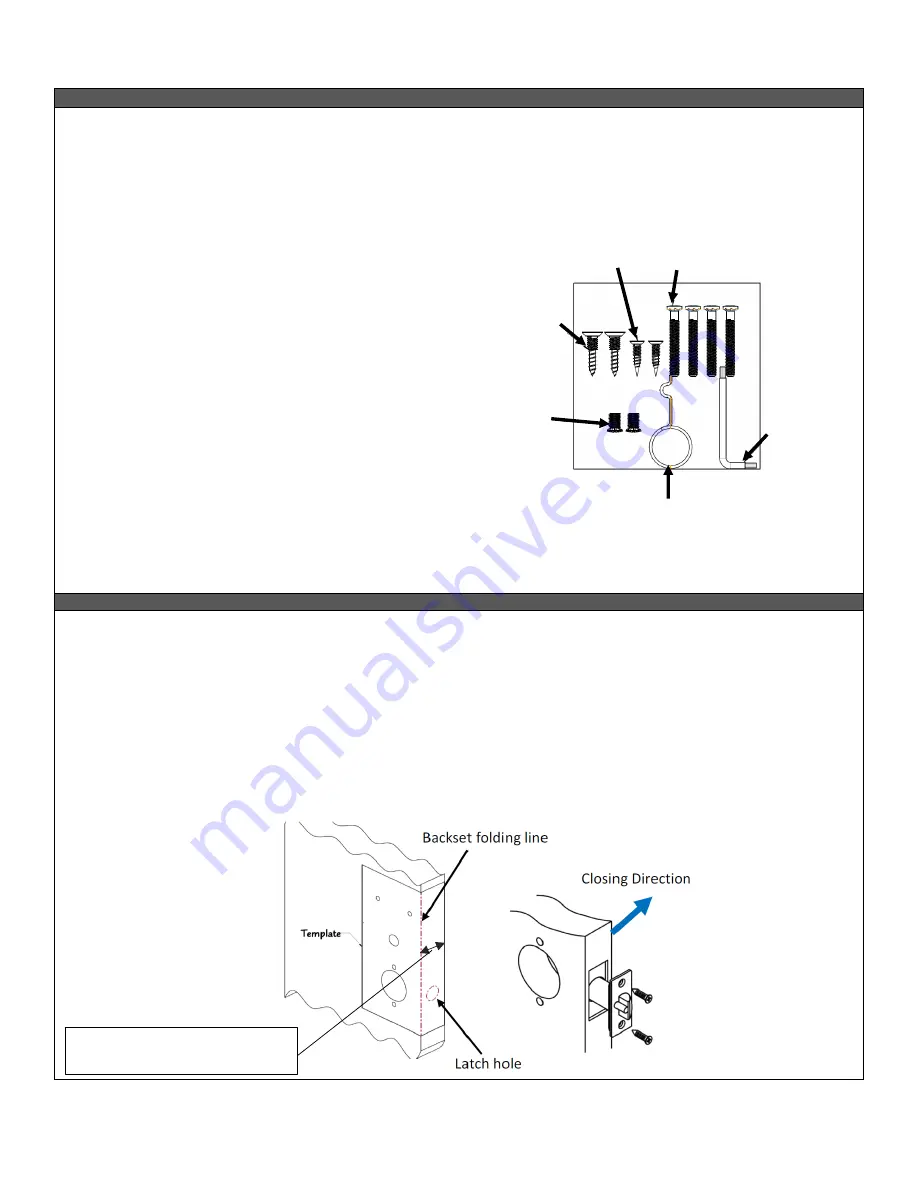

B. DOOR PREPARATION

1.

Doors: Steel or Wood

2.

Door thickness range: 1-

3⁄8" (35mm) ~ 2" (51mm).

3.

Match the Backset of your Proxess C-Series lockset to the corresponding installation (either 2-

3⁄8" [60 mm] or 2

-

3⁄4" [70

mm] Backset).

4.

Place the installation template onto door and mark ho

les. Drill the Ø2 1⁄8" (54 mm) first, then drill the two Ø5/16" (8mm)

holes for lock chassis mounting followed by two Ø3/8" (9.5mm) holes for exterior Housing Assembly mounting. Drill the

Ø13⁄16" (20 mm) hole for through wiring. Drill the Ø1" (25 mm) cross

bore hole for the latch last.

5.

Insert latch into Ø1" hole and hold it parallel to door face, mark outline and remove latch. Chisel 11⁄64" (4.3mm) deep or

until faceplate is flush with the edge of the door. Insert latch into the Ø1" hole again, making certain that the latch bolt

bevel faces direction of closing door (see section E for Lock Handing).

6.

Secure the latch to the door using two #8x3/4" screws (SB2).

(SB1)

(SB2)

(SB3)

(SB4)

(SB5)

(SB6)

Backset thickness

–

note that lock

is preset to standard 1¾ inch door

(SB3)

(SB5)

(SB2)

(SB1)

(SB6)

(SB4)

Summary of Contents for PX10100001

Page 1: ...C Series Service manual...