ProxxonTools.com

Manual

TG 250/E

- 2 -

Your device does not work properly? Please read the operating

instructions again carefully. If the unit is in fact defective, please

send it to:

PROX-Tech, Inc.

2555 Tate Blvd SE

PO Box 1909

Hickory, NC 28603-1909

We will respond in a prompt and reliable manner. You can also

order any necessary spare parts from this address.

Important: A short description of the fault helps us to respond

even more quickly. When returning a device within the warranty

period, please enclose the relevant purchase receipt.

Made in Germany by PROXXON GmbH, D-54518 Niersbach,

Im Spanischen 18-24

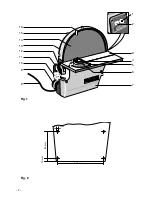

Fig. 1

Fig. 2

4

5

6

3

1

2

10

mm

80

mm

135 mm

ø 4,5 mm

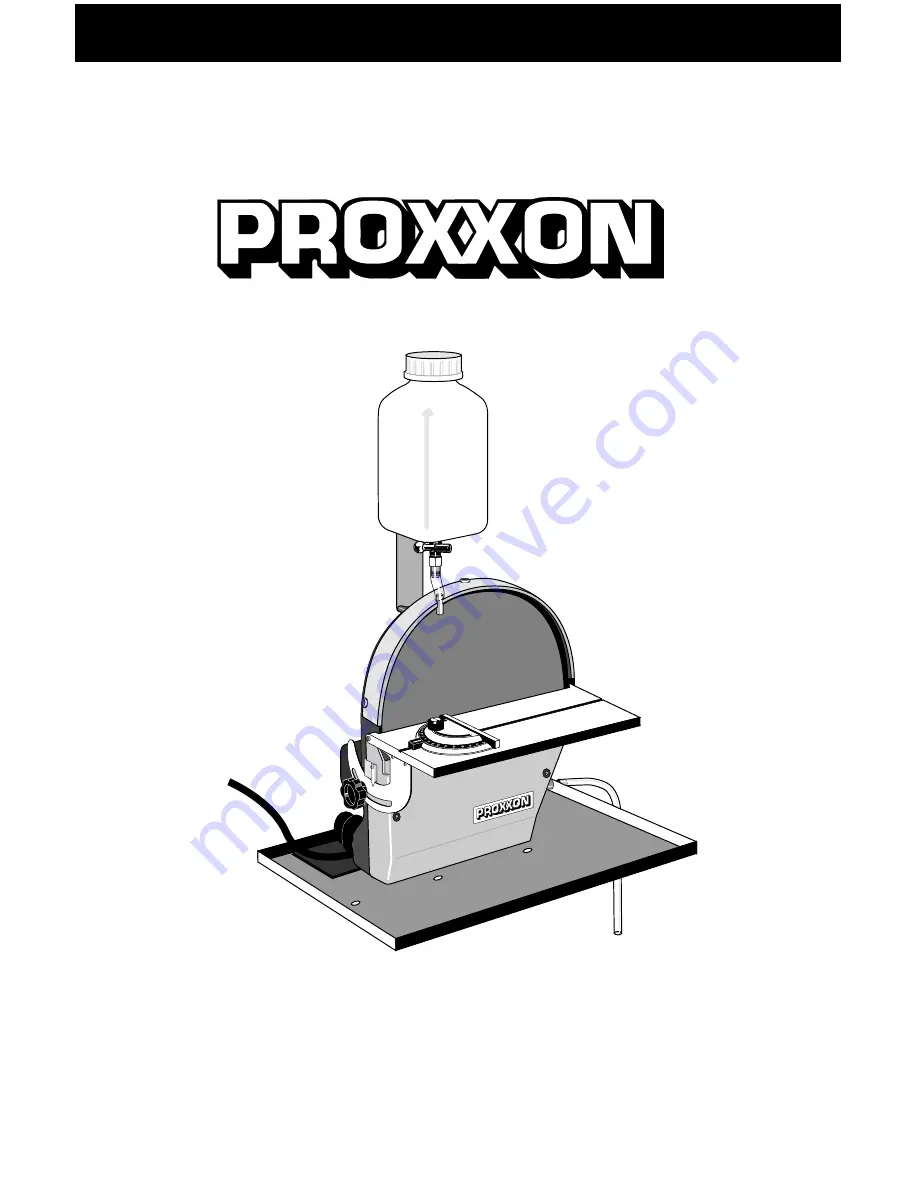

16

15

14

13

12

11

10

9

8

1

2

3

4

5

6

7