- 8 -

Note:

When applying the abrasive disk on the grinding plate,

start from the centre and work outwards.

3. Apply the top half of the abrasive disk on the grinding

plate precisely in the correct position.

4. Rotate the grinding plate approx. 180°, remove the

second half or the protective foil and use the same

procedure to apply the disk.

5. Reattach the protective cover.

Working with the Disk sander

Important!

Safe and precision working practice can only be ensured

with the unit properly secured!

Do not leave the unit switched on if unsupervised.

1. Switch on the disk sander.

2. Adjust the rotational speed of the disk sander using the

speed controller

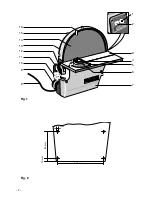

1 (fig. 1).

3. Place the work piece on the working table, guide it

gently and carefully.

4. Always exert pressure on the working table rather than

against the abrasive disk.

Note:

Please note the following items in order to ensure good

grinding results:

1. Do not overload the unit (if the fuse blows, only use an

original fuse (1.25 T) as a replacement)!

2. The disk sander is primarily designed for grinding

precise angles. The more accurately the work piece is

pre-cut, the quicker and easier it will be to produce

precise angles and the less abrasive disks will be

required to perform the task.

3. Please note the dissimilar grinding speeds for the

abrasive disk (fig. 6):

inner diameter = low speed

outer diameter= high speed

4. The abrasive disk turns in an anti-clockwise direction.

For this reason, only grind on the left half of the working

table.

Important!

Only use abrasive disks which are in a flawless

condition. Replace worn abrasive disks promptly.

Grinding a Mitre with the Working Table Inclined

1. Release the clamping bolt

2 (fig. 5) and set the working

table to the desired angle (e.g., 45°).

2. Tighten clamping bolt 2.

3. Set angular limit stop

1 (fig. 5) to position "0"

With horizontally set working table

1. Release the clamping bolt

2 (fig. 6) and set the working

table horizontally (indicator at "0").

2. Tighten clamping bolt 2.

3. Set the angular limit stop

1 (fig. 6) to the desired angle

(e.g., 45°).

Liquid Cooling System

We recommend that the liquid cooling system is attached

when grinding iron, steel and non-ferrous metals, as well

as stone, tiles, ceramics (not included in scope of supply,

available as an accessory).

The heat arising from grinding operations is dissipated by

supplying coolant, thus improving the resulting surface

quality.

Dust Extract Connection

In order to permit a dust-free working environment, the

disk sander is equipped with a vacuum cleaner connection

for dust extraction.

Important!

When using both a vacuum cleaner (as a dust extract unit)

and the liquid cooling unit, ensure that the vacuum cleaner

is suitable for aqua cleaning as well.

1. Connect the vacuum cleaner hose to the connection

spigot

9 (fig. 1).

2. Switch on the vacuum cleaner.

3. Switch on the disk sander, grind the work piece.