- 9 -

Cleaning and Care

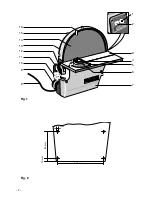

Your disk sander was developed for minimal maintenance,

however regular cleaning is required to ensure a long

trouble-free service life.

Caution!

Always disconnect the mains plug prior to cleaning and

maintenance operations.

1. Regularly inspect the mains cable for damage.

2. Ensure the abrasive disk is securely seated and in

perfect condition, if necessary replace the abrasive disk.

3. Thoroughly clean the disk sander after use.

Warning!

To avoid fire or toxic reaction, never use gasoline, naphtha,

acetone, lacquer thinner, or similar highly volatile solvents

to clean the disk sander.

Do not allow brake fluids, gasoline, or penetrating oils to

come in contact with the plastic parts. They contain

chemicals that can damage or destroy plastics.

Turn switch OFF and always remove plug from power

source before making any adjustments or repairs.

All electrical or mechanical repairs should be done only by

qualified service technicians.

When servicing use only PROXXON replacement parts.

Use of any other parts may create a hazard or cause

product damage.

Any attempt to repair or replace electrical parts on this disk

sander may create a hazard unless repair is done by a

qualified service technician. Repair service is available at

your PROXXON service center (You find the address at

address at the back of this manual)