PM381 User Manual

Rev.1.4

www.prttech.com

11

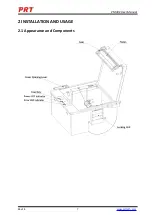

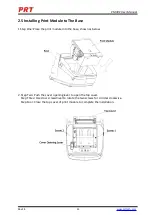

2.5 Installing Print Module to The Base

1.Step One: Place the print module into the base, shown as below.

2. Step Two: Push the cover opening lever to open the top cover.

Step Three: Use cross screwdriver to rotate the two screws for 4 circles clockwise.

Step Four: Close the top cover of print module to complete the installation.