Soft foot

107

5 .17 .1 Parallel soft foot correction

If two diagonal values are roughly equal and significantly higher than the other two,

parallel soft foot can be assumed as a first solution.

5 .17 .2 Angular soft foot correction

If one value is significantly higher than the others, then angular soft foot can be

suspected.

The ‘problem foot’ or machine frame is probably bent or distorted in some way. In

this case loosen the bolt and examine the foot more closely. Use a feeler gauge to

establish the variation of the gap and use these measurements to sketch the shape

and dimensions for a ‘stair stepped shim wedge’.

If the soft foot is purely ‘angular’ then the stepped shim will vary in thickness from

about zero to twice the value displayed by the computer.

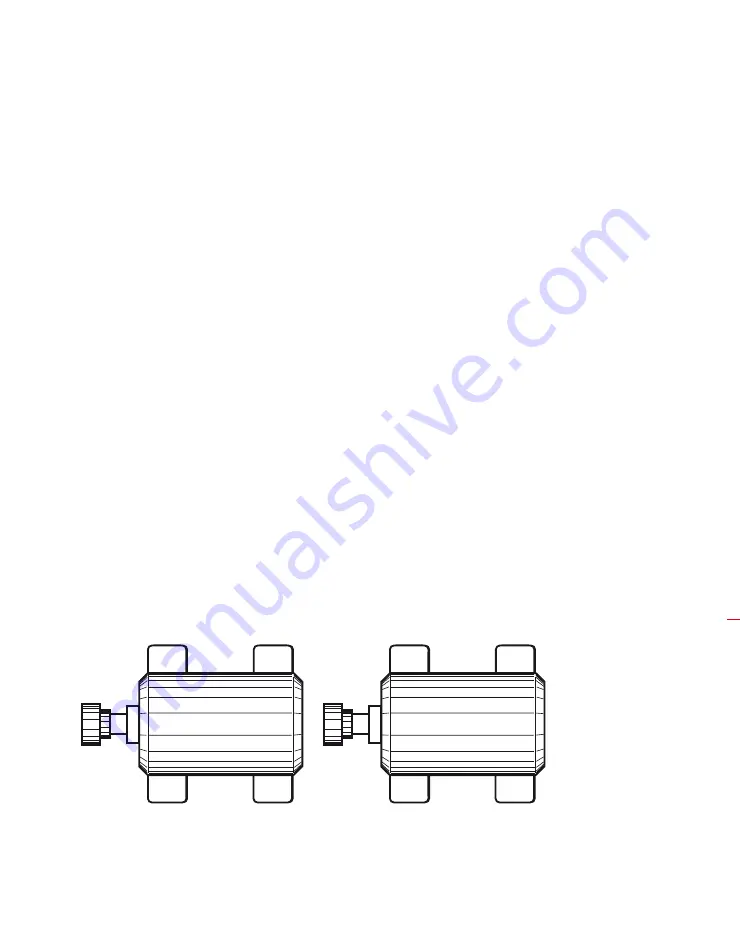

Parallel soft foot

The machine is rocking on

two diagonal feet which

are longer than the other

two. In this example, the

correction would be to

place a 0.89mm shim under

foot ‘b‘ (the foot with the

largest gap)

Angular soft foot

The base of one or more

feet is at an angle to the

foundation and is only

partly in contact.

0 .10

0 .74

b

0 .18

0 .13

0 .18

0 .76

0 .10

a

0 .89

c

d

a

b

d

c

Summary of Contents for OPTALIGN smart RS5 BT

Page 10: ...OPTALIGN smart RS5 BT handbook 10 Page intentionally left blank ...

Page 16: ...OPTALIGN smart RS5 BT handbook 16 This page intentionally left blank ...

Page 28: ...OPTALIGN smart RS5 BT handbook 28 Page intentionally left blank ...

Page 38: ...OPTALIGN smart RS5 BT handbook 38 This page intentionally left blank ...

Page 112: ...OPTALIGN smart RS5 BT handbook 112 This page intentionally left blank ...

Page 174: ...OPTALIGN smart RS5 BT handbook 174 This page intentionally left blank ...

Page 194: ...OPTALIGN smart RS5 BT handbook 194 This page intentionally left blank ...