133

7.2 Cardan drive machines

This section describes the aligning of cardan shafts using the cardan shaft bracket lite

ALI 2.874 SET iS used in conjunction with OPTALIGN smart RS5 BT system. Cardan

drives are installed and operate with a large offset between the driver and the driven

shaft. The cardan shaft is set at a considerable angle (usually 4° to 6°) in order to

ensure sufficient lubricant circulation, which in turn prevents the universal joints from

seizing. Excessive misalignment of such a configuration leads to rapid fluctuation of

the driven shaft RPM during operation, which holds grave consequences for electron-

ically-controlled synchronous and asynchronous AC drive motors.

Precise alignment reduces the rotational irregularities of the cardan shaft to a minimum,

so that the uneven bearing loading during cardan shaft rotation is also minimized, the

service life of the components is extended and the chance of unexpected machine

failure is reduced.

The measurement procedure described here allows precise measurement of machines

joined by cardan shafts over distances of up to 3 m (10 ft) and shaft offsets of up to

400 mm (15 3/4 in).

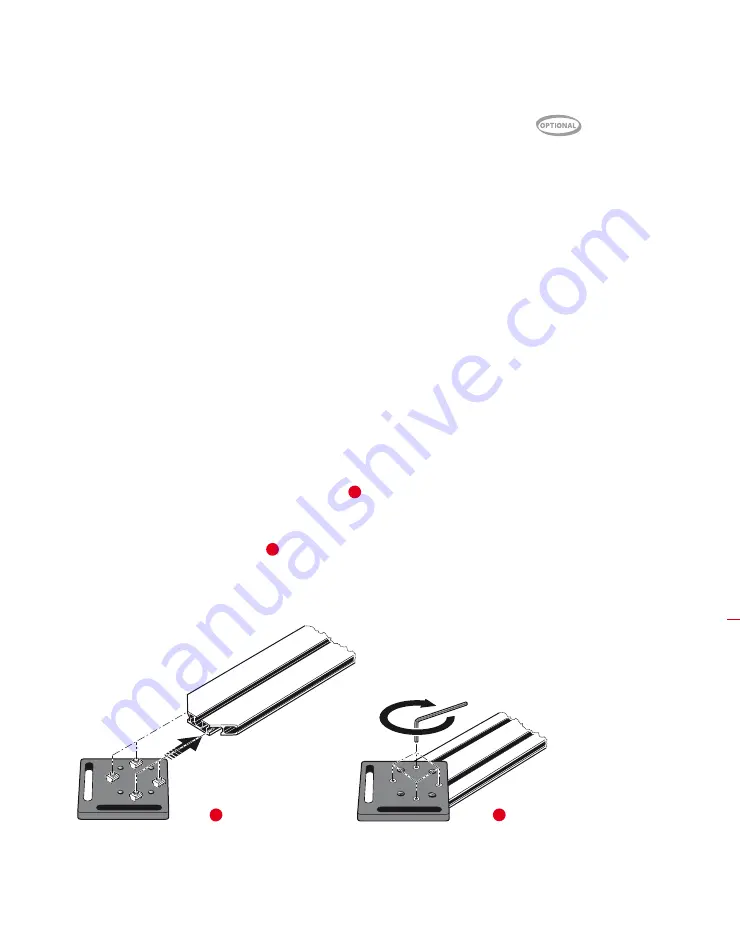

7 .2 .1 Mounting the faceplate to the rail

1. Slide the the faceplate down the rail as shown in

1

below. The four T-nuts

should sit in the grooves.

2. After positioning the faceplate on the rail, tighten the four socket head screws

using the provided M5 allen key [

2

].

Cardan drive machines

1

2

Summary of Contents for OPTALIGN smart RS5 BT

Page 10: ...OPTALIGN smart RS5 BT handbook 10 Page intentionally left blank ...

Page 16: ...OPTALIGN smart RS5 BT handbook 16 This page intentionally left blank ...

Page 28: ...OPTALIGN smart RS5 BT handbook 28 Page intentionally left blank ...

Page 38: ...OPTALIGN smart RS5 BT handbook 38 This page intentionally left blank ...

Page 112: ...OPTALIGN smart RS5 BT handbook 112 This page intentionally left blank ...

Page 174: ...OPTALIGN smart RS5 BT handbook 174 This page intentionally left blank ...

Page 194: ...OPTALIGN smart RS5 BT handbook 194 This page intentionally left blank ...