6-7

ROTALIGN 01.2000

Machine preparation

Certain preparations should be made before beginning any alignment

to ensure efficient measurement and successful results.

Ensure that the machine cannot accidently be started before

commencing work.

Solid, flat foundation

A solid, rigid foundation is required to obtain correct, lasting shaft

alignment that allows long-term uninterrupted machine service.

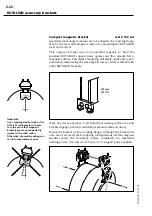

Machine mobility

Shaft alignment in theory and in practice

If the machine to be moved stands directly on the foundations, it

cannot be lowered for alignment correction. Therefore, it is generally

advisable to start with about 2 mm (80 mils) of shims beneath the

feet of both machines.

Precut shims such as single-thickness PERMABLOC or laminated

LAMIBLOC shims, available individually or as complete assortments

in carrying cases, should be on hand before beginning alignment (see

page 6-9). Horizontal alignment can be made easier and more precise

if hydraulic or screw-type positioning aids are available. The "ham-

mer method" is not only inexact, but it can also damage the machine

housing and bearings (by chatter marking).

Rigid couplings

Rigid couplings, typically found on turbines, must be loosened before

measurement so that they do not distort the alignment condition.

How this is done depends on the type of machine:

Steam turbines with single bearing shafts: Remove the coupling

bolts, split the coupling faces 2-3 mm (1/8") and insert a couple of

undersize dummy bolts.

Steam turbines with two bearing shafts: The coupling faces normally

locate together; the coupling must, therefore, be split sufficiently in

order to dislocate them. Alternatively, there may be a spacer

component which can be dropped out and the two halves linked with

a bar.

Gas turbines: These are usually fitted with a spacer shaft to

accommodate large thermal growths. Either a) remove the spacer

and use the Pass mode (page 4-36) or b) loosen the coupling as above

and use the Multipoint mode (page 4-36).

Tip:

Adjustment screws can easily be

made be tack welding a bolt to the

foundation and inserting a screw

vertical

2 mm

horizontal

WARNING!

Summary of Contents for ROTALIGN ALI 3.500

Page 13: ...1 10 ROTALIGN 01 2000 This page intentionally left blank ...

Page 103: ...4 66 ROTALIGN 01 2000 This page intentionally left blank ...

Page 121: ...5 18 ROTALIGN 01 2000 This page intentionally left blank ...

Page 143: ...6 22 ROTALIGN 01 2000 This page has intentionally been left blank ...

Page 158: ...6 37 ROTALIGN 01 2000 This page intentionally left blank ...