6-10

ROTALIGN 01.2000

The ROTALIGN measurement principle

12

3

6

9

ENTER

MAIN

AUX

.....BATT ..... ........ ........

CHARGE

SLEEP

Shaft alignment in theory and in practice

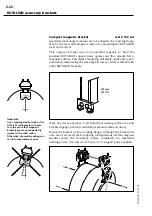

To measure the misalignment, the shafts are rotated. The laser beam

shines onto the receiver detector, and during rotation any misalign-

ment in the shaft causes the laser beam to change its position in the

receiver.

The exact location of the beam is recorded by registering its

coordinates along with the corresponding rotation angle of the

shafts. This takes place at a number of points during shaft rotation

through 360° or less. Several different measurement procedures

(described on page 4-34) are available to handle special situations

such as uncoupled shafts and limited rotation.

The computer then uses the minute displacements measured by the

detector to calculate the current alignment condition. It displays the

resulting machine alignment diagram complete with coupling align-

ment values and position values for the machine feet. The former

allow the operator to compare the situation at hand with prescribed

tolerances.

Checking alignment with vibration analysis

One very impressive method of demonstrating the importance of

good alignment for smooth operation of rotating equipment is

comparative vibration measurement (for example, using

PRÜFTECHNIK VIBROSPECT

®

FFT or VIBROTIP

®

) before and after

alignment. A comprehensive vibration analysis can also point out

other specific machine problems.

Summary of Contents for ROTALIGN ALI 3.500

Page 13: ...1 10 ROTALIGN 01 2000 This page intentionally left blank ...

Page 103: ...4 66 ROTALIGN 01 2000 This page intentionally left blank ...

Page 121: ...5 18 ROTALIGN 01 2000 This page intentionally left blank ...

Page 143: ...6 22 ROTALIGN 01 2000 This page has intentionally been left blank ...

Page 158: ...6 37 ROTALIGN 01 2000 This page intentionally left blank ...