6-12

ROTALIGN 01.2000

Inconsistent measurements:

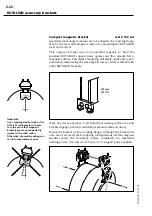

1) Brackets incorrectly mounted: are the brackets slipping or loose

or mounted at an angle? (page 4-11). Were the brackets

accidentally knocked during or between measurements?

2) Measurement range too small or too few points: rotate through a

larger angle with more measurement points (page 4-33)

3) Machine preparation problem: excessive bearing play? Check

with Soft foot function (page 4-29). Is the foundation stable? If

suspect, split the coupling and measure with Pass mode (page

4-36). Is the coupling too stiff, e.g. membrane coupling? See

page 6-7.

4) Are the receiver and laser lenses clean? (page 6-36)

Difficulties in alignment:

1) Poor measurement, see reasons listed above.

2) Are corrections being made in the wrong direction? See the rules

on pages 4-34 and 4-50.

3) Check Soft foot (page 4-29)

4) Check machine preparation details (page 4-10). Is the foundation

stable? Are your horizontal moves reasonably accurate with jack

screws or similar?

Troubleshooting guide

Summary of Contents for ROTALIGN ALI 3.500

Page 13: ...1 10 ROTALIGN 01 2000 This page intentionally left blank ...

Page 103: ...4 66 ROTALIGN 01 2000 This page intentionally left blank ...

Page 121: ...5 18 ROTALIGN 01 2000 This page intentionally left blank ...

Page 143: ...6 22 ROTALIGN 01 2000 This page has intentionally been left blank ...

Page 158: ...6 37 ROTALIGN 01 2000 This page intentionally left blank ...