4-11

ROTALIGN 01.2000

2. Mount the brackets

Mount the brackets on either side of the machine coupling, and both

at the same angle.

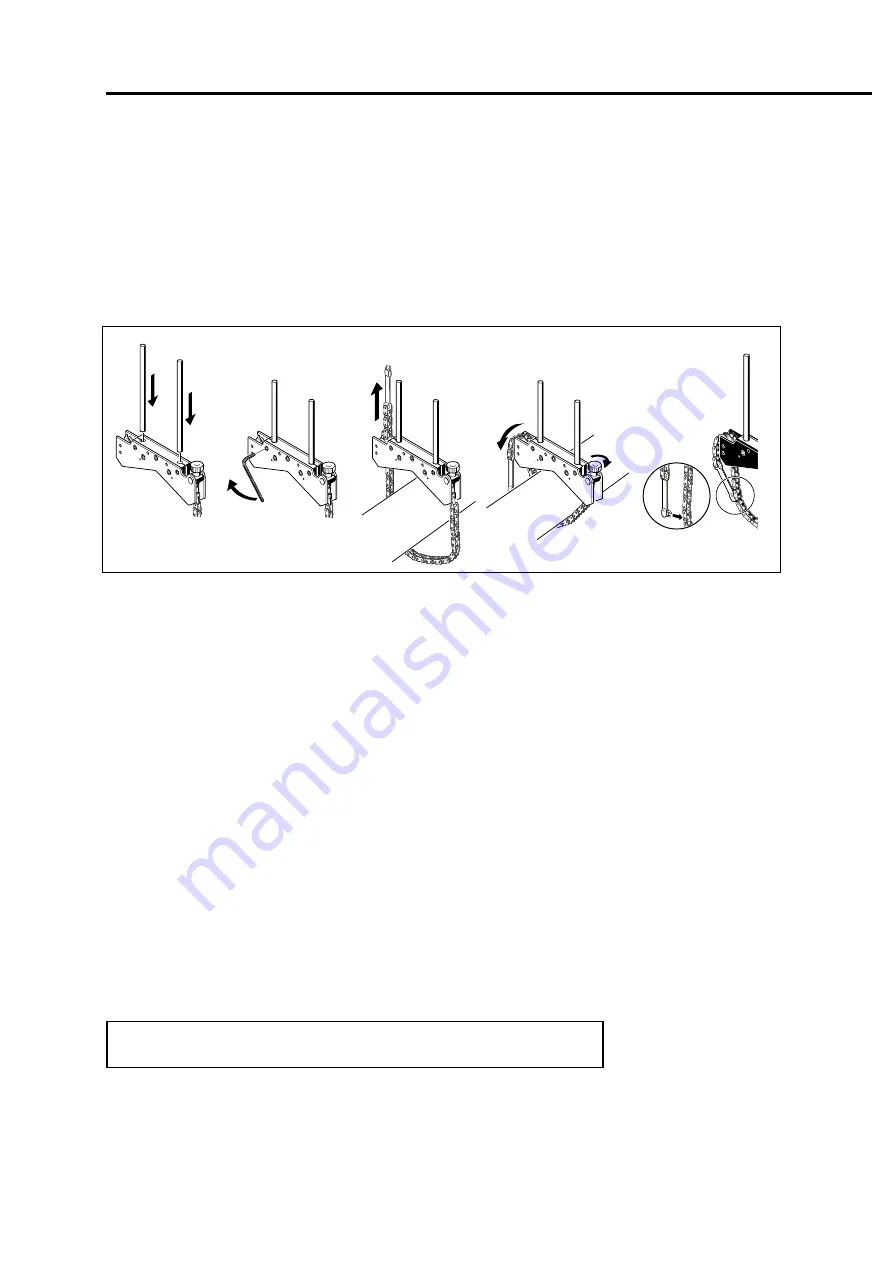

Here is how to fit the compact chain-type brackets:

1.

Choose the shortest support posts which will still allow the laser

beam to pass over the coupling flange. Insert the support posts

into the bracket.

2.

Fasten them in place by tightening the hex screws on the sides of

the bracket frame.

3.

Place the bracket on the shaft or coupling, wrap the chain around

the shaft and feed it through the other side of the bracket: if the

shaft is smaller than the width of the bracket frame, insert the

chain from the inside of the bracket as shown above; if the shaft

is larger than the bracket width, insert the chain into the frame

from the outside.

4.

Catch the chain loosely on the anchor peg.

5.

Turn the bracket thumbscrew to tighten the assembly onto the

shaft.

6.

Small clips are provided to secure the loose ends of the chain

back onto itself.

Now the bracket should be tight upon the shaft. Do not push or pull

on the bracket to check, since that would only loosen its mounting.

Important: The brackets MUST be correctly mounted to ensure

accurate measurements.

To remove the brackets, first loosen the thumbscrew, then remove

the chain from its anchor peg.

Note: the compact chain-type brackets cover most situations, but in

cramped or special cases, others may be required, see pages 6-18 -

6-22. If one or both sides of the coupling cannot be rotated, you will

require the sliding magnetic brackets, pages 4-36 and 6-18.

Note: Tighten the support posts

into the bracket first! Otherwise

this may be difficult once the

bracket is mounted on the shaft.

1

2

3

4

5

6

F

Note

Horizontal machine alignment - mount the brackets

Summary of Contents for ROTALIGN ALI 3.500

Page 13: ...1 10 ROTALIGN 01 2000 This page intentionally left blank ...

Page 103: ...4 66 ROTALIGN 01 2000 This page intentionally left blank ...

Page 121: ...5 18 ROTALIGN 01 2000 This page intentionally left blank ...

Page 143: ...6 22 ROTALIGN 01 2000 This page has intentionally been left blank ...

Page 158: ...6 37 ROTALIGN 01 2000 This page intentionally left blank ...