Soft foot

133

5.5 Soft foot

Soft foot is the condition of machine frame distortion. Any cause that results in

machine frame distortion when the machine is anchored to its foundation is a soft

foot. Some principal causes are:

› Non-coplanar machine mounting surfaces,

› Deformed machine frame or feet,

› External forces e.g. from connecting pipe or bracket,

› Improper shimming or dirty machine feet.

› Too many shims under a machine foot (a maximum of 3 should be used)

The consequences of forcibly tightening down the feet are deformed machine

frames, bent shafts and distorted bearings. This leads to high vibration and premature

failure.

Soft foot should be checked before aligning the shafts, and this can be done quickly

and conveniently with the aid of the ROTALIGN Ultra iS Shaft soft foot function. With

the sensALIGN laser and sensor mounted on the shaft in the usual way, the system is

able to sense any machine movement when the machine bolts are loosened individu-

ally. By entering the machine dimensions, the computer is able to calculate, from shaft

movement, by how much each foot has moved as it is loosened.

Once foot movements have been established, the results are interpreted and

translated into shim thicknesses to be placed under the feet. How straightforward

this is, depends on the type of soft foot present.

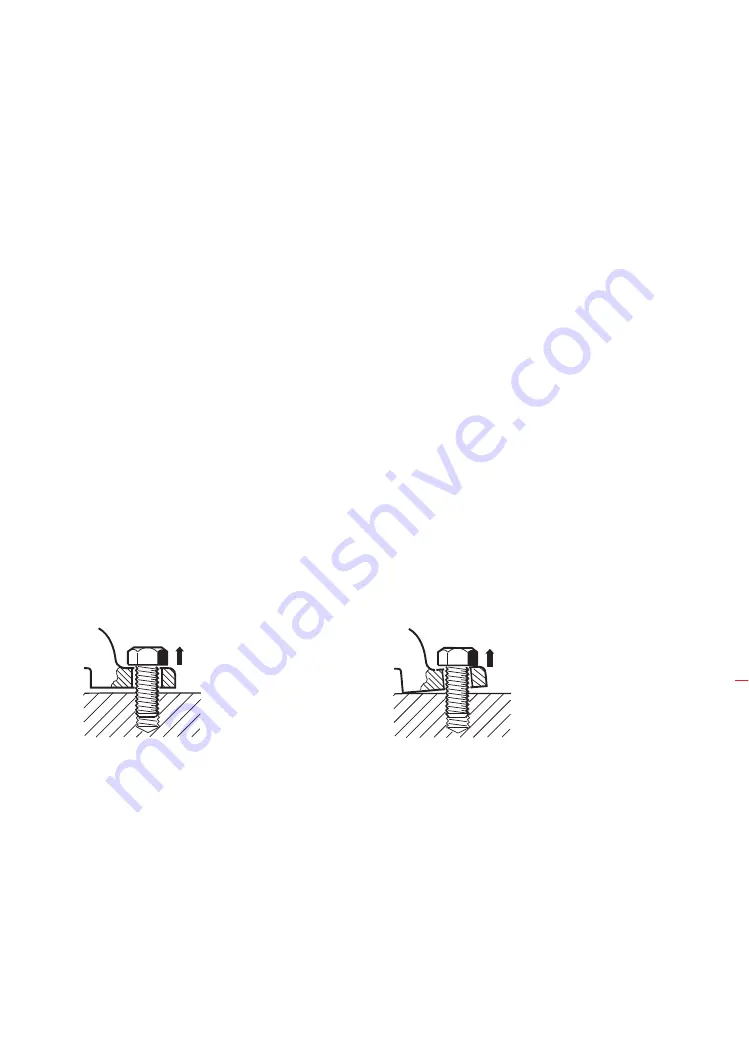

Parallel soft foot

One or more feet are

too short or too long.

This usually results in the

machine rocking on the

longer feet. This is corrected

by shimming the shorter

feet.

Angular soft foot

The base of the foot is at

an angle to its foundation

and they are only partly in

contact. In this case, suspect

foot is checked with a feeler

gauge and corrected by

building a custom ‘shim

wedge’ or machining the

underside of the foot

Summary of Contents for ROTALIGN Ultra iS

Page 1: ...ROTALIGN Ultra iS Operating handbook Shaft alignment...

Page 11: ...ROTALIGN Ultra iS Shaft handbook 10 This page intentionally left blank...

Page 56: ...55 Horizontal shaft alignment 1 2 4 5 6...

Page 123: ...ROTALIGN Ultra iS Shaft handbook 122 Page intentionally left blank...

Page 141: ...ROTALIGN Ultra iS Shaft handbook 140 This page intentionally left blank...

Page 177: ...ROTALIGN Ultra iS Shaft handbook 176 Page intentionally left blank...

Page 207: ...ROTALIGN Ultra iS Shaft handbook 206 Page intentionally left blank...

Page 213: ...ROTALIGN Ultra iS Shaft handbook 212 Declaration of conformity...