155

2. Out of tolerance machines may be repositioned with the help of the MOVE

function (refer to section 4.13).

3. Remeasure to determine the new alignment condition by pressing

m

, then

repeating steps 9-11 in section 6.2.6.

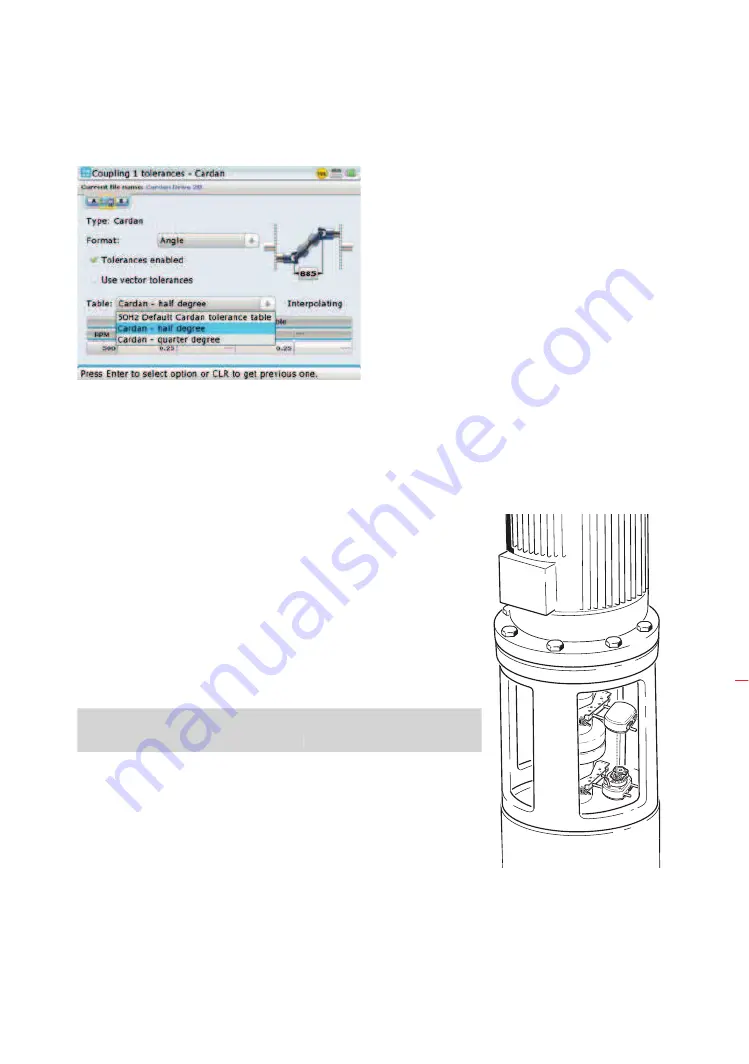

6.3 Flanged machines

A typical vertical machine arrangement comprises one machine mounted on

top of the other using a bolted flange.

Flange-mounted machines may have a vertical or horizontal orientation. In

either case, alignment corrections are made directly at the flange.

Angularity is corrected by inserting or removing shims between the flanges.

ROTALIGN Ultra iS calculates the shimming thickness for each flange bolt.

Offset is corrected by positioning the flange laterally.

6.3.1 Overview - vertical machinery

Before commencing with this section, please acquaint yourself with

‘Horizontal shaft alignment’ in chapter 4.

sensALIGN laser and sensor are mounted on either side of the coupling as

for horizontal machines, with sensALIGN laser on the shaft of the machine

designated stationary. The electronic inclinometer cannot determine the

rotation angle of vertical shafts; therefore measurements must be taken

on vertical machines using Static measurement mode. The eight 45°

measurement positions used with this procedure must be marked accordingly

on the machine.

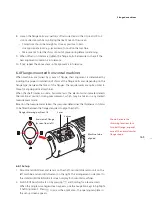

The tolerances table

may also be accessed as

described in section 5.4.7.

Note

Before commencing with this section, please acquaint yourself with

‘Horizontal shaft alignment’ in chapter 4.

Flanged machines

Summary of Contents for ROTALIGN Ultra iS

Page 1: ...ROTALIGN Ultra iS Operating handbook Shaft alignment...

Page 11: ...ROTALIGN Ultra iS Shaft handbook 10 This page intentionally left blank...

Page 56: ...55 Horizontal shaft alignment 1 2 4 5 6...

Page 123: ...ROTALIGN Ultra iS Shaft handbook 122 Page intentionally left blank...

Page 141: ...ROTALIGN Ultra iS Shaft handbook 140 This page intentionally left blank...

Page 177: ...ROTALIGN Ultra iS Shaft handbook 176 Page intentionally left blank...

Page 207: ...ROTALIGN Ultra iS Shaft handbook 206 Page intentionally left blank...

Page 213: ...ROTALIGN Ultra iS Shaft handbook 212 Declaration of conformity...