ROTALIGN

®

Ultra iS Shaft handbook

160

6.3.4 Measure

1. After entering the required dimensions, press

m

and proceed to center the

laser beam.

For vertically oriented machine trains, static measurement mode is selected

automatically.

2. Rotate the shafts to the first measurement position. If using the coupling

housing numbering convention, the reference mark and the measurement

position 0 should be aligned or matched to each other.

3. Press

e

to take the first measurement point.

4. Rotate shaft to the second measurement position (e.g. 1:30). If the chosen

measurement position does not correspond to the position selected automati-

cally on the display, use the navigation keys to manually position sensALIGN

sensor and laser at desired position on the display.

5. Take the maximum number of measurement points to maximize the quality of

results.

Note

For vertically oriented machine trains, static measurement mode is selected

automatically.

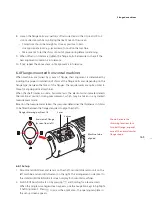

In Static mode

measurement, the

inner ring displays the

measurement quality

which is active only when

measurement is finished

using the “Measurement”

screen context menu item

‘Stop’. In this example,

the measurement quality

is good and therefore the

colour code green.

Summary of Contents for ROTALIGN Ultra iS

Page 1: ...ROTALIGN Ultra iS Operating handbook Shaft alignment...

Page 11: ...ROTALIGN Ultra iS Shaft handbook 10 This page intentionally left blank...

Page 56: ...55 Horizontal shaft alignment 1 2 4 5 6...

Page 123: ...ROTALIGN Ultra iS Shaft handbook 122 Page intentionally left blank...

Page 141: ...ROTALIGN Ultra iS Shaft handbook 140 This page intentionally left blank...

Page 177: ...ROTALIGN Ultra iS Shaft handbook 176 Page intentionally left blank...

Page 207: ...ROTALIGN Ultra iS Shaft handbook 206 Page intentionally left blank...

Page 213: ...ROTALIGN Ultra iS Shaft handbook 212 Declaration of conformity...