161

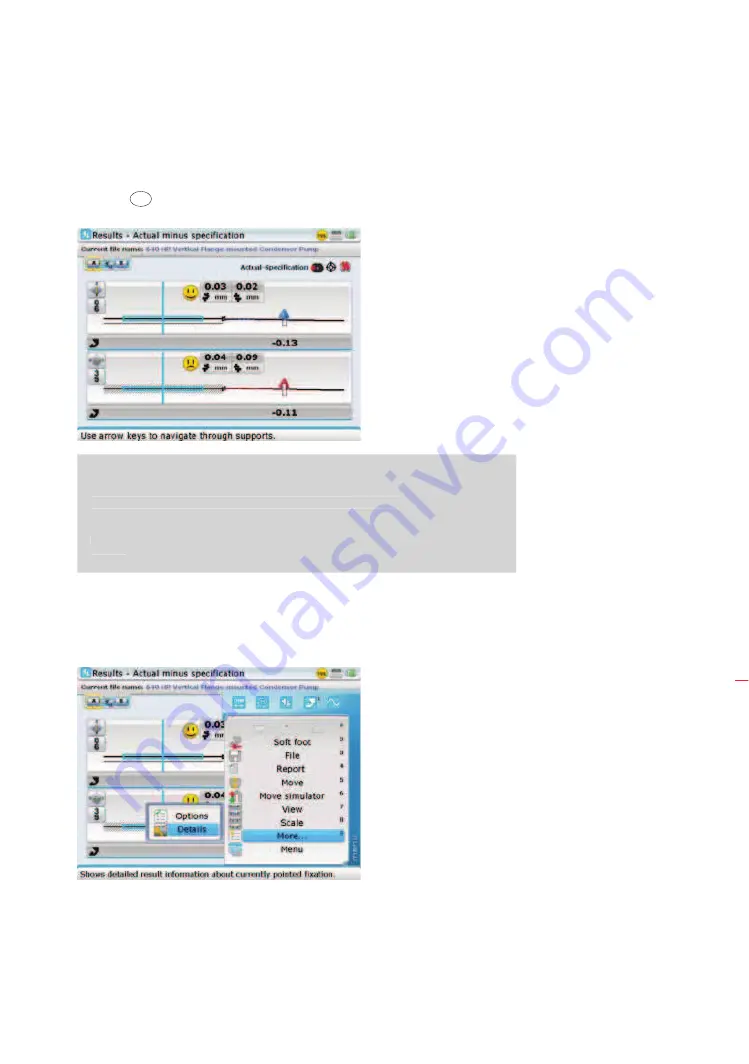

6.3.5 Results

1. Press

RES

to evaluate results.

Sign convention

POSITIVE GAP opens towards 0:00 or 3:00

POSITIVE OFFSET if the top machine is towards 0:00 or 3:00

Remember, viewpoint is always determined by looking from the sensor towards

the laser emitter. Note the little white clock face on the laser serves as a reminder

of this.

2. Use the “Results” screen sub menu item ‘Details’ to view the shimming

corrections for each flange bolt. Press

q

while in the results screen then use

the navigation keys to highlight the submenu item ‘Details’.

3. With ‘details’ highlighted, press

e

to confirm selection. The “Flange

corrections” screen appears.

The results screen shows the

coupling gap and coupling

offset in the 0-6 and 3-9

directions. Offset corrections

in the side and top view are

also shown.

In this example, the 0-6

correction indicates moving

the flange by 0.13 mm

towards 0:00 and by 0.11

mm towards 3:00.

The screen values represent

POSITION.

Sign convention

POSITIVE GAP opens towards 0:00 or 3:00

POSITIVE OFFSET if the top machine is towards 0:00 or 3:00

Remember, viewpoint is always determined by looking from the sensor towards

the laser emitter. Note the little white clock face on the laser serves as a reminder

of this.

Note

Flanged machines

Summary of Contents for ROTALIGN Ultra iS

Page 1: ...ROTALIGN Ultra iS Operating handbook Shaft alignment...

Page 11: ...ROTALIGN Ultra iS Shaft handbook 10 This page intentionally left blank...

Page 56: ...55 Horizontal shaft alignment 1 2 4 5 6...

Page 123: ...ROTALIGN Ultra iS Shaft handbook 122 Page intentionally left blank...

Page 141: ...ROTALIGN Ultra iS Shaft handbook 140 This page intentionally left blank...

Page 177: ...ROTALIGN Ultra iS Shaft handbook 176 Page intentionally left blank...

Page 207: ...ROTALIGN Ultra iS Shaft handbook 206 Page intentionally left blank...

Page 213: ...ROTALIGN Ultra iS Shaft handbook 212 Declaration of conformity...