ROTALIGN

®

Ultra iS Shaft handbook

162

Flange correction details are displayed only when the cursor is on a movable

element.

4. To choose the shimming solution best suited for

the situation at hand, press

q

while in the results

screen. The context menu appears.

Use the navigation keys to highlight the appropriate mode then press

e

to

confirm selection.

› (–) mode indicates all negative shimming

› (+) mode indicates all positive shimming

› (±) mode indicates optimized shimming. In this mode, half of the corrections

will positive, and the other half negative.

› (0+) mode indicates zero plus shimming. In this mode, one bolt position is

forced to zero and the rest are positive.

› (0–) mode indicates zero minus shimming. In this mode, one bolt position is

forced to zero and the rest are negative.

Note

Flange correction details are displayed only when the cursor is on a movable

element.

Press

RES

to cycle

through the 0-6, 3-9 and

both results’ views. The

three views may also

be accessed using the

“Results” screen context

menu item ‘View --’ where

-- can be either ‘both’,

‘0-6’ or ‘3-9’.

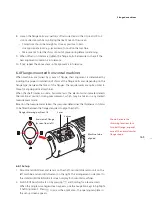

The flange corrections

screen shows the shimming

corrections for each flange

bolt. The value for each bolt

position appears on the

shim table and as an inset

next to the flange pattern.

Any bolt position can be

selected by pressing either

p

(counterclockwise) or

o

(clockwise).

The offset corrections to be

performed on the flange are

displayed along the sides of

the flange schematic.

Summary of Contents for ROTALIGN Ultra iS

Page 1: ...ROTALIGN Ultra iS Operating handbook Shaft alignment...

Page 11: ...ROTALIGN Ultra iS Shaft handbook 10 This page intentionally left blank...

Page 56: ...55 Horizontal shaft alignment 1 2 4 5 6...

Page 123: ...ROTALIGN Ultra iS Shaft handbook 122 Page intentionally left blank...

Page 141: ...ROTALIGN Ultra iS Shaft handbook 140 This page intentionally left blank...

Page 177: ...ROTALIGN Ultra iS Shaft handbook 176 Page intentionally left blank...

Page 207: ...ROTALIGN Ultra iS Shaft handbook 206 Page intentionally left blank...

Page 213: ...ROTALIGN Ultra iS Shaft handbook 212 Declaration of conformity...