163

Good quality shims such as PERMABLOC, MYLAR and LAMIBLOC should be

used. Contact your local PRÜFTECHNIK representative for details.

5. Offset is corrected using the ‘Move’ function. These corrections may also be

simulated using the Move simulator. Both these functions may be accessed via

the “Results” screen context menu. Press

q

then use

f

/

g

to highlight

the required Move function from the context menu that appears.

6. With the context menu item ‘Move’ highlighted, press

e

to confirm selection.

A hint requesting the setting of the sensor angle appears on the screen.

7. Use the navigation keys to position the sensor image on the screen to

correspond to the angular position of sensALIGN laser and sensor. Press

e

to

confirm selected position. The Move function auto starts.

Note

Good quality shims such as PERMABLOC, MYLAR and LAMIBLOC should be

used. Contact your local PRÜFTECHNIK representative for details.

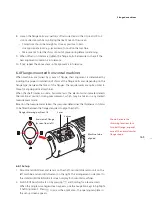

The Move simulator is

used to simulate flange

offset corrections. Note

that the simulated

values may often not

result in the alignment

being within tolerance

as shimming corrections

are not considered in

vertical alignment Move

simulation. For details

on the Move simulator

you may refer to section

4.14.2a-b.

In this example, we will

proceed with live Move.

The context menu item

‘Move’ is highlighted using

f

/

g

.

Flanged machines

Summary of Contents for ROTALIGN Ultra iS

Page 1: ...ROTALIGN Ultra iS Operating handbook Shaft alignment...

Page 11: ...ROTALIGN Ultra iS Shaft handbook 10 This page intentionally left blank...

Page 56: ...55 Horizontal shaft alignment 1 2 4 5 6...

Page 123: ...ROTALIGN Ultra iS Shaft handbook 122 Page intentionally left blank...

Page 141: ...ROTALIGN Ultra iS Shaft handbook 140 This page intentionally left blank...

Page 177: ...ROTALIGN Ultra iS Shaft handbook 176 Page intentionally left blank...

Page 207: ...ROTALIGN Ultra iS Shaft handbook 206 Page intentionally left blank...

Page 213: ...ROTALIGN Ultra iS Shaft handbook 212 Declaration of conformity...