165

8. Loosen the flange bolts and perform offset corrections in the 0 to 6 and 9 to 3

o’clock directions while monitoring the live Move on the screen.

› Corrections should be brought as close as possible to zero.

› Use appropriate tools (e.g. jackscrews) to position the machine.

› Take care not to let the shims slip out of place during lateral positioning.

9. When offset is in tolerance, tighten the flange bolts. Remeasure to check if the

new alignment condition is in tolerance.

10. If not, repeat the above steps until alignment is in tolerance.

6.4 Flange-mounted horizontal machines

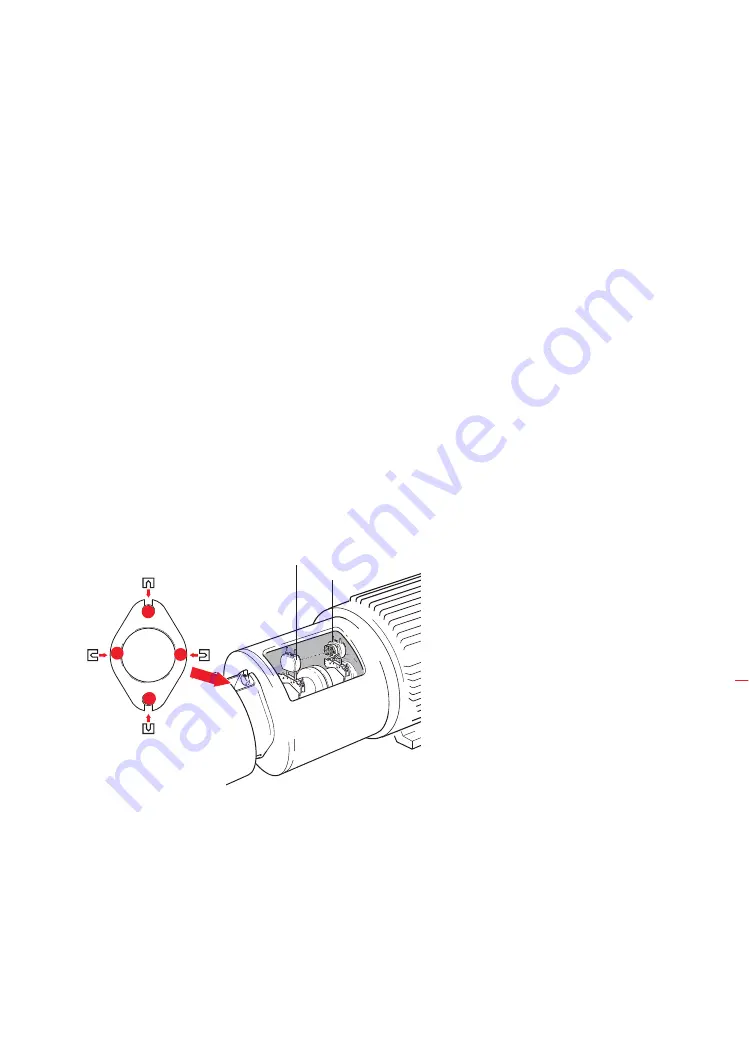

When machines are joined by means of flange, their alignment is determined by

inserting the proper combination of shims at the flange bolts and, depending on the

flange type, between the faces of the flanges. The requirements are quite similar to

those for aligning vertical machines.

When the shaft rotates around a horizontal axis, the electronic inclinometer detects

the rotational position during measurement, which may be taken in any desired

measurement mode.

Based on the measurements taken, the computer determines the thicknesses of shims

to be fitted between the flanges required to align the shafts.

6.4.1 Set-up

1. Mount sensALIGN laser and sensor on the shaft. sensALIGN laser mounts on the

left machine and sensALIGN sensor on the right. This arrangement is identical to

the standard ROTALIGN Ultra iS screen display for horizontal machines.

2. Switch ROTALIGN Ultra iS on by pressing

e

and holding for a few seconds.

When the program manager screen appears, use the navigation keys to highlight

‘Shaft Alignment’. Press

e

to access the application. The opening template in

the set-up screen appears.

Laser

Sensor

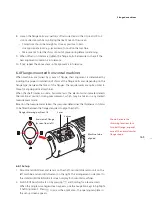

Shown here are the

shimming locations for a

two-bolt flange, a special

case of the normal circular

flange shape.

End view of flange

(as seen from left)

Machine to be

aligned

Flange shimming positions 1-4

2

4

3

1

Flanged machines

Summary of Contents for ROTALIGN Ultra iS

Page 1: ...ROTALIGN Ultra iS Operating handbook Shaft alignment...

Page 11: ...ROTALIGN Ultra iS Shaft handbook 10 This page intentionally left blank...

Page 56: ...55 Horizontal shaft alignment 1 2 4 5 6...

Page 123: ...ROTALIGN Ultra iS Shaft handbook 122 Page intentionally left blank...

Page 141: ...ROTALIGN Ultra iS Shaft handbook 140 This page intentionally left blank...

Page 177: ...ROTALIGN Ultra iS Shaft handbook 176 Page intentionally left blank...

Page 207: ...ROTALIGN Ultra iS Shaft handbook 206 Page intentionally left blank...

Page 213: ...ROTALIGN Ultra iS Shaft handbook 212 Declaration of conformity...