169

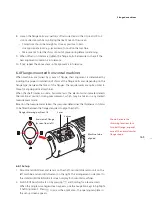

The flange is depicted as viewed from the right machine toward the left. The bolts

in the figure correspond to the bolts (or shimming positions) on the flange, with the

top position corresponding to number “1”. The respective offset appears on the top

half of the screen.

6.4.5 Shimming

Loosen the bolts and fit the shims according to the values given in the table. Try to

avoid any lateral movement of the machine while doing so. When finished, retighten

bolts.

6.4.6 Remeasure

Press

m

and take a new set of readings before beginning offset corrections. The

results should now show little if any shimming corrections.

6.4.7 Live Move to eliminate offset

Start live Move using the “Results” screen context menu item ‘Move’.

Do not loosen the machine anchor bolts until live Move starts. Move the machine

laterally (for horizontal) while viewing the screen.

In this example, the

horizontal offset value is

0.06 mm positive.

The table on the right

lists the calculated shim

corrections. The interpreta-

tion of the shim corrections

has been described in

section 6.3.5.

Flanged machines

Summary of Contents for ROTALIGN Ultra iS

Page 1: ...ROTALIGN Ultra iS Operating handbook Shaft alignment...

Page 11: ...ROTALIGN Ultra iS Shaft handbook 10 This page intentionally left blank...

Page 56: ...55 Horizontal shaft alignment 1 2 4 5 6...

Page 123: ...ROTALIGN Ultra iS Shaft handbook 122 Page intentionally left blank...

Page 141: ...ROTALIGN Ultra iS Shaft handbook 140 This page intentionally left blank...

Page 177: ...ROTALIGN Ultra iS Shaft handbook 176 Page intentionally left blank...

Page 207: ...ROTALIGN Ultra iS Shaft handbook 206 Page intentionally left blank...

Page 213: ...ROTALIGN Ultra iS Shaft handbook 212 Declaration of conformity...