37

4.2.3 Rigid couplings

Rigid couplings must be loosened before measurement so that they do not distort the

alignment condition.

4.2.4 Shaft play and coupling backlash

Axial shaft play is detected and compensated for in alignment results (but affects

machine operation).

4.2.5 Soft foot

Soft foot causes the machine frame distortion every time the bolts are loosened or

tightened, making proper alignment difficult or impossible.

4.2.6 Thermal growth, alignment targets, tolerances

These values can be obtained from the individual machine specifications, and then

entered into the program. In addition, a built in thermal growth calculator can help

you derive these values from the observed changes in temperature.

4.2.7 Measurement separation

As the system requires no mechanical connections (such as cantilevered dial indicator

brackets) to span over the coupling during measurement, alignment may easily be

performed over large laser – sensor separations.

Note that over very large distances the shafts and coupling may sag, and the machines

may need to be aligned to take this into account. Refer to the machine manufacturer’s

specifications.

4.3 Check soft foot

Refer to section 5.5 for soft foot.

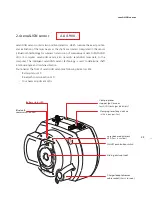

4.4 Mount the brackets

Mount the brackets on either side of the coupling on either the shafts or on the solid

coupling hubs, and both at the same rotational position.

Please note the following in order to obtain the highest possible measurement

accuracy and to avoid damage to equipment:

Ensure that the brackets fit solidly onto their mounting surfaces!

Do not use self-constructed mounting brackets, or modify the original

bracket configuration supplied by PRÜFTECHNIK Alignment (for example,

do not use support posts longer than those supplied with the bracket).

CAUTION

Ensure that the brackets fit solidly onto their mounting surfaces!

Do not use self-constructed mounting brackets, or modify the original

bracket configuration supplied by PRÜFTECHNIK Alignment (for example,

do not use support posts longer than those supplied with the bracket).

Horizontal shaft alignment

Summary of Contents for ROTALIGN Ultra iS

Page 1: ...ROTALIGN Ultra iS Operating handbook Shaft alignment...

Page 11: ...ROTALIGN Ultra iS Shaft handbook 10 This page intentionally left blank...

Page 56: ...55 Horizontal shaft alignment 1 2 4 5 6...

Page 123: ...ROTALIGN Ultra iS Shaft handbook 122 Page intentionally left blank...

Page 141: ...ROTALIGN Ultra iS Shaft handbook 140 This page intentionally left blank...

Page 177: ...ROTALIGN Ultra iS Shaft handbook 176 Page intentionally left blank...

Page 207: ...ROTALIGN Ultra iS Shaft handbook 206 Page intentionally left blank...

Page 213: ...ROTALIGN Ultra iS Shaft handbook 212 Declaration of conformity...