67

4.13.2 Sign convention

The following sign convention is used in the evaluation of alignment results.

With left machine stationary, gap is positive when open at top or side away from

viewer. The viewer is considered to be standing in front of the machines as they

appear on the display.

Both vertical and horizontal results show the foot position relative to the stationary

machine centerline. Positive values indicate that machine is upwards or away from

viewer. Negative values indicate that machine is downwards or towards the viewer.

4.13.3 Alignment quality

The ‘smiley’ symbol by the coupling results indicates the degree to which the measured

alignment condition meets tolerances. The smiley face appears only when tolerances

have been enabled (see section 4.9).

If all results lie within tolerance, no alignment corrections are necessary.

4.14 Align machine

To align your machine you need to move it vertically by shimming the feet, and

horizontally by shifting it sideways. You can perform these operations in either order

or simultaneously.

4.14.1 Shim first

It is recommended to perform vertical corrections first, since the horizontal

condition is easily affected by the process of loosening anchor bolts and inserting/

removing shims, whereas the vertical condition is less prone to being affected

when performing horizontal moves. You may need to recheck soft foot before

proceeding.

Excellent

Acceptable

Out of tolerance

Note

If all results lie within tolerance, no alignment corrections are necessary.

Note

It is recommended to perform vertical corrections first, since the horizontal

condition is easily affected by the process of loosening anchor bolts and inserting/

removing shims, whereas the vertical condition is less prone to being affected

when performing horizontal moves. You may need to recheck soft foot before

proceeding.

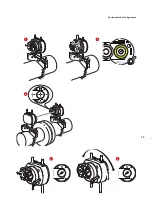

Horizontal shaft alignment

Summary of Contents for ROTALIGN Ultra iS

Page 1: ...ROTALIGN Ultra iS Operating handbook Shaft alignment...

Page 11: ...ROTALIGN Ultra iS Shaft handbook 10 This page intentionally left blank...

Page 56: ...55 Horizontal shaft alignment 1 2 4 5 6...

Page 123: ...ROTALIGN Ultra iS Shaft handbook 122 Page intentionally left blank...

Page 141: ...ROTALIGN Ultra iS Shaft handbook 140 This page intentionally left blank...

Page 177: ...ROTALIGN Ultra iS Shaft handbook 176 Page intentionally left blank...

Page 207: ...ROTALIGN Ultra iS Shaft handbook 206 Page intentionally left blank...

Page 213: ...ROTALIGN Ultra iS Shaft handbook 212 Declaration of conformity...