ROTALIGN Ultra iS Shaft handbook

86

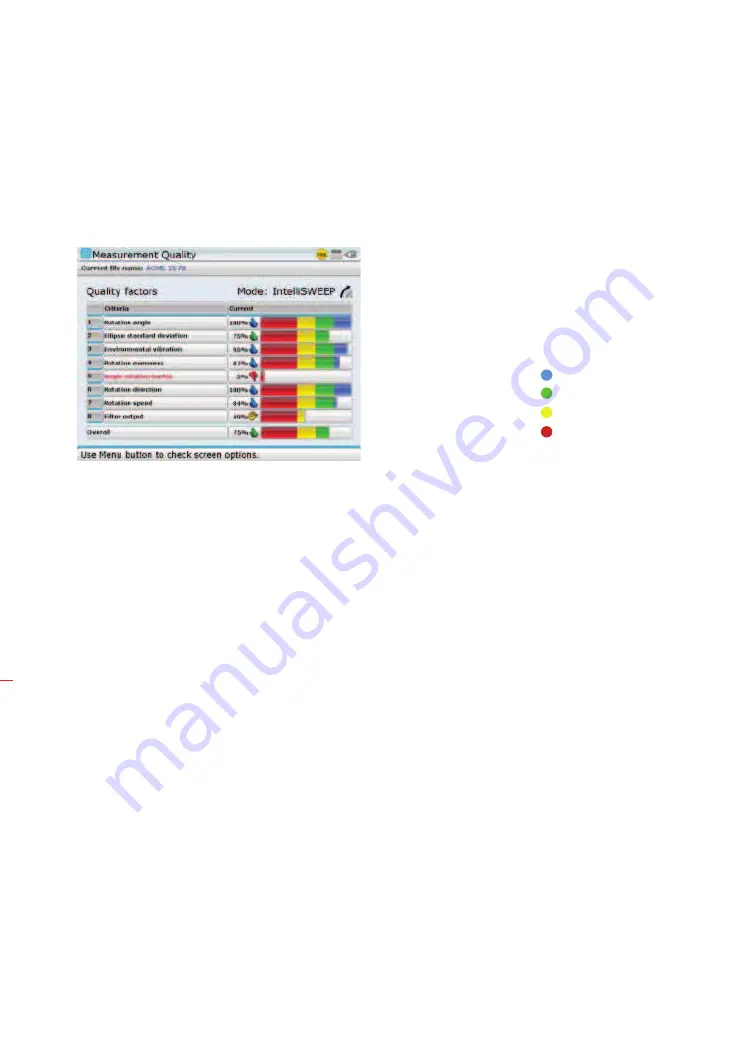

With ‘Detailed quality’ highlighted, press

e

to confirm selection. The “Measurement

quality” screen opens. The screen displays all the factors and the respective weighting

used to determine the measurement quality.

Measurement quality is based on the following measurement and environmental

criteria:

Rotation angle – the angle through which sensALIGN sensor/shaft is rotated

during measurement

Ellipse standard deviation – the root mean square deviation of the measurement

points on the calculated ellipse

Environmental vibration – the level of external vibration e.g. from neighbouring

running machine(s)

Rotation evenness – the smoothness of the measurement rotation e.g. if there is

any friction during the rotation that ‘jerks’ the shaft

Angle rotation inertia – abrupt changes in the measurement rotation speed e.g.

releasing and re-applying a break during the rotation

Rotation direction – change in the measurement rotational direction

Rotational speed – how fast sensALIGN sensor/shaft is rotated during

measurement

Filter output – the amount of measurement data filtered out

5.1.2 Multipoint measurement

This mode is used to measure shafts which are either difficult to turn continuously

or allow measurement only in certain rotational positions. The method can also

be used to measure uncoupled shafts, nonrotatable shafts, sleeve bearings, white

metal bearings and journal (radial) bearings, shafts that are difficult to turn, shafts

with herky-jerky rotation, situations with long spans or severe misalignment that will

readily cause the beam to fall out of range.

Measurement quality

is depicted using the

following colour codes:

— excellent

— acceptable

— not acceptable

— poor

In this example, when all

quality factors have been

considered, the resulting

measurement quality

of 75% is classified as

excellent with the colour

code blue.

Summary of Contents for ROTALIGN Ultra iS

Page 1: ...ROTALIGN Ultra iS Operating handbook Shaft alignment...

Page 11: ...ROTALIGN Ultra iS Shaft handbook 10 This page intentionally left blank...

Page 56: ...55 Horizontal shaft alignment 1 2 4 5 6...

Page 123: ...ROTALIGN Ultra iS Shaft handbook 122 Page intentionally left blank...

Page 141: ...ROTALIGN Ultra iS Shaft handbook 140 This page intentionally left blank...

Page 177: ...ROTALIGN Ultra iS Shaft handbook 176 Page intentionally left blank...

Page 207: ...ROTALIGN Ultra iS Shaft handbook 206 Page intentionally left blank...

Page 213: ...ROTALIGN Ultra iS Shaft handbook 212 Declaration of conformity...