89

After finishing measurement, press

RES

to view results.

If only one shaft is not easily rotatable while the other can be freely rotated,

always mount the sensor on the nonrotatable shaft (use the magnetic sliding

bracket ALI 2.230). Do NOT mount the laser emitter on the not-easily-rotatable

shaft, even if this means setting up your laser and sensor opposite to the way

you normally would for alignment purposes. You can always invert the movable

and stationary machines by using the static feet utility in the results screen.

Enter all dimensions in accordance with your actual set-up, following the normal

orientation of the laser and sensor in the dimensions screen.

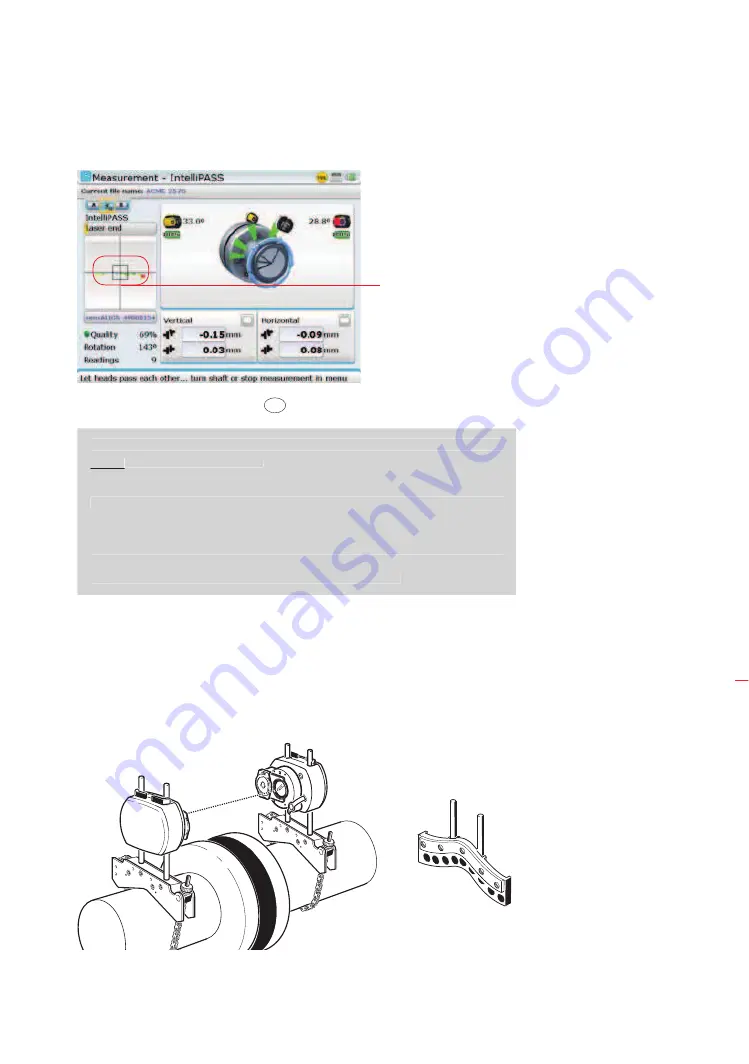

The path traced by the laser

beam as it passes the sensor

is plotted on the detector

display. Readings are taken

in the middle sector of the

detector surface. This is the

section where laser position

appears as green dots.

Readings are not taken

where laser position appears

as yellow dots.

Note

If only one shaft is not easily rotatable while the other can be freely rotated,

always

y mount the sensor on the nonrotatable shaft (use the magnetic sliding

bracket ALI 2.230). Do NOT mount the laser emitter on the not-easily-rotatable

shaft, even if this means setting up your laser and sensor opposite to the way

you normally would for alignment purposes. You can always invert the movable

and stationary machines by using the static feet utility in the results screen.

Enter all dimensions in accordance with your actual set-up, following the normal

orientation of the laser and sensor in the dimensions screen.

It is recommended to take

several sets of readings

and then compare them

for repeatability in the

measurement table

(accessible from the

“Measurement” screen

context menu item ‘Table’.

If necessary average

together multiple sets

of readings for greater

accuracy.

Measurement modes

Uncoupled shafts

:

Mount laser and sensor

using chain-type brackets

For not easily rotatable

shaft(s)

:

Mount sensor using

magnetic sliding bracket

ALI 2.230.

Magnetic sliding bracket

ALI 2.230

sensALIGN laser

sensALIGN sensor

Summary of Contents for ROTALIGN Ultra iS

Page 1: ...ROTALIGN Ultra iS Operating handbook Shaft alignment...

Page 11: ...ROTALIGN Ultra iS Shaft handbook 10 This page intentionally left blank...

Page 56: ...55 Horizontal shaft alignment 1 2 4 5 6...

Page 123: ...ROTALIGN Ultra iS Shaft handbook 122 Page intentionally left blank...

Page 141: ...ROTALIGN Ultra iS Shaft handbook 140 This page intentionally left blank...

Page 177: ...ROTALIGN Ultra iS Shaft handbook 176 Page intentionally left blank...

Page 207: ...ROTALIGN Ultra iS Shaft handbook 206 Page intentionally left blank...

Page 213: ...ROTALIGN Ultra iS Shaft handbook 212 Declaration of conformity...