93

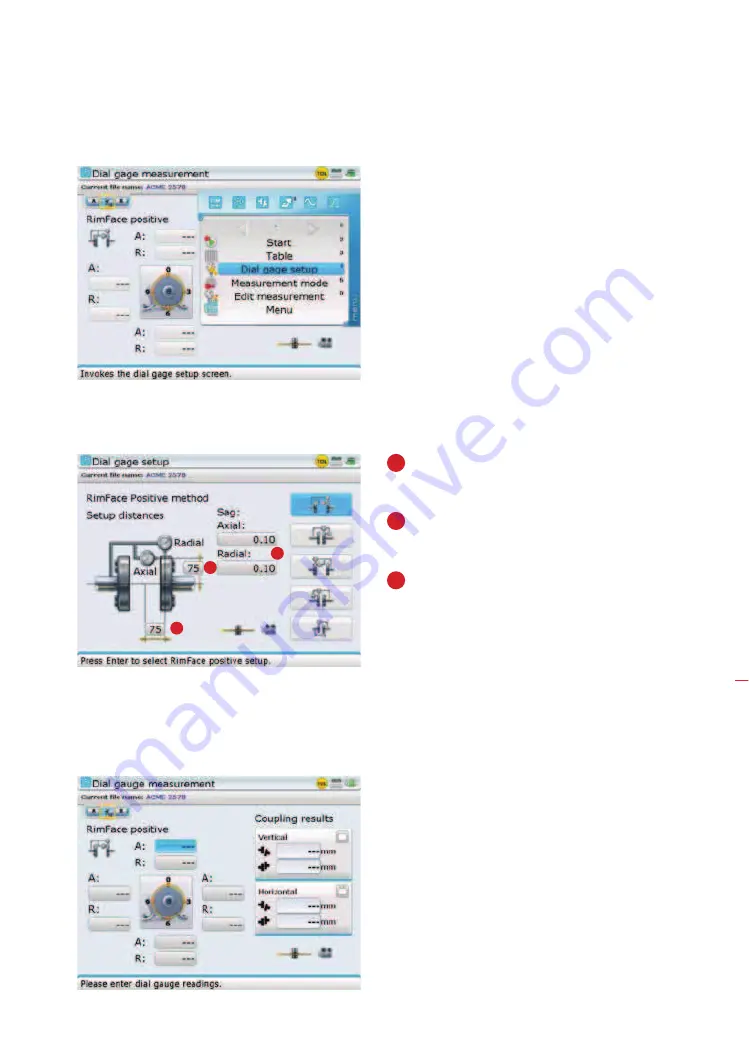

4. Press

e

to confirm selection, then proceed to enter required axial and radial

dimensions, and sag values using the data entry keys .

5. After entering the required dimensions and the

amount of bracket sag, press

ß

to return to the

dial gauge measurement screen. To enter the dial gauge values, press

e

. The

cursor highlights the 12:00 o’clock rim value box.

Alternatively, use the “Dial

gauge measurement”

screen context menu item

‘Start’ to begin entering the

dial gauge values.

Measurement modes

1

2

3

1

In this method, enter

the radius of the axial gauge

from the shaft center.

2

Here, we enter distance

from the radial gauge to the

coupling center.

3

Enter radial and axial

sag values.

Values are entered directly

using the data entry keys

and confirmed by pressing

either

e

or

ß

.

Summary of Contents for ROTALIGN Ultra iS

Page 1: ...ROTALIGN Ultra iS Operating handbook Shaft alignment...

Page 11: ...ROTALIGN Ultra iS Shaft handbook 10 This page intentionally left blank...

Page 56: ...55 Horizontal shaft alignment 1 2 4 5 6...

Page 123: ...ROTALIGN Ultra iS Shaft handbook 122 Page intentionally left blank...

Page 141: ...ROTALIGN Ultra iS Shaft handbook 140 This page intentionally left blank...

Page 177: ...ROTALIGN Ultra iS Shaft handbook 176 Page intentionally left blank...

Page 207: ...ROTALIGN Ultra iS Shaft handbook 206 Page intentionally left blank...

Page 213: ...ROTALIGN Ultra iS Shaft handbook 212 Declaration of conformity...