11.8 Composite materials

Composite materials (woodfill, copperfill, bronzefill, glow-in-the-dark, carbon or aramid

composites and many others) consist of main plastic base and second material in the form of

dust. These materials tend (with the exception of wood composites) to be very abrasive,

therefore hardened nozzle is strongly suggested for long-term printing. Larger nozzle is

recommended while printing with wood composites (0.5 mm and up). Please use

corresponding print settings in Slic3r or PrusaControl as print parameters can be very

different depending on plastic base.

The first step in polishing is sanding. It’s a good idea to start with a coarse grit size (80) and

slowly move up the grit table. After sanding a big improvement in polish can be achieved

with steel wool or brass brush. If you’re still not happy with the finish, you can try wet

sanding with a very fine grit (1500).

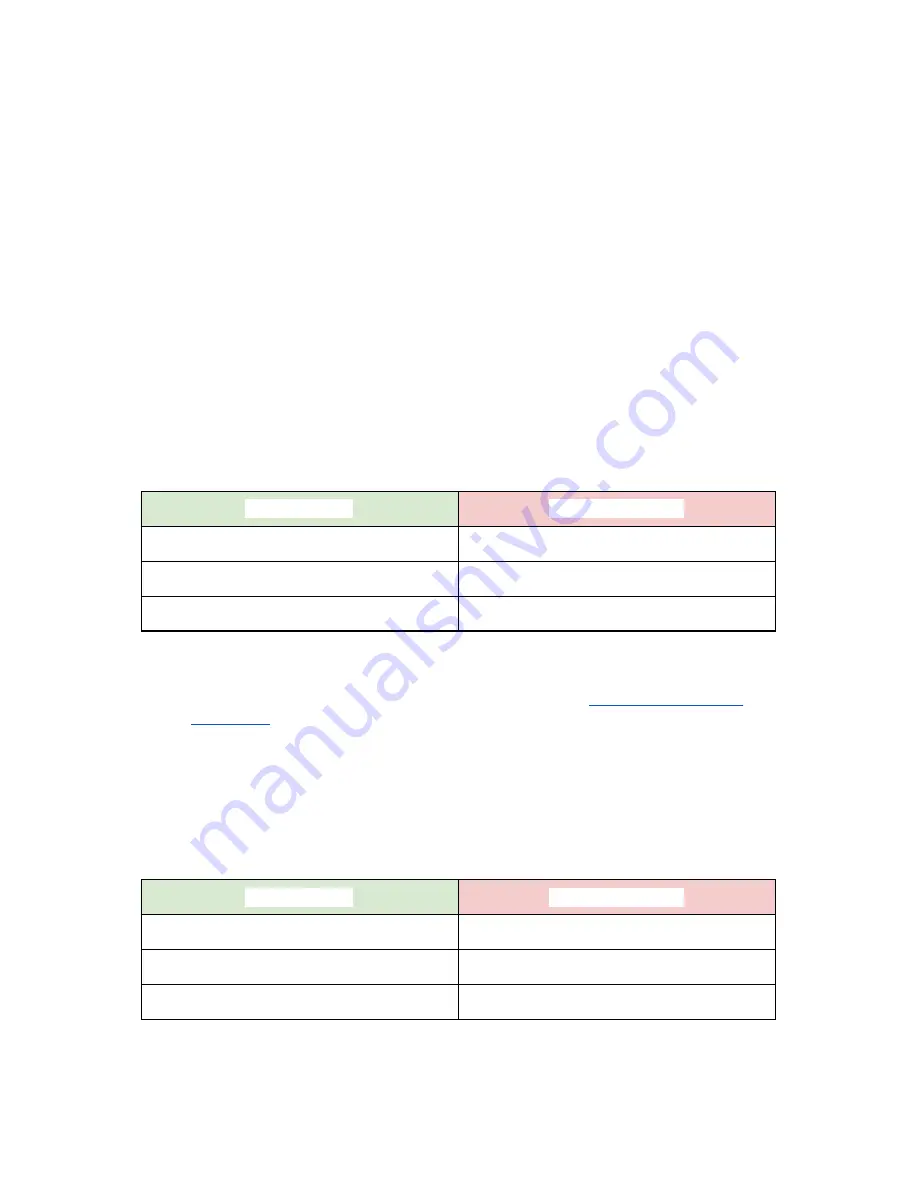

ADVANTAGES

DISADVANTAGES

Easy to print

Needs hardened nozzle

No warping

Great look after post-processing

● Nozzle temperature:

190 - 210 °C

● Bed temperature:

50 - 70 °C (bigger object -> higher temp.)

● Heatbed:

Make sure the surface is clean as described in

6.3.2 PEI print surface

preparation

chapter.

11.9 ASA

Acrylonitrile-styrene-acryl (ASA) is a material with properties similar to ABS, its main benefit

is increased weather and UV resistance. Other advantage is overall dimensional stability. To

achieve cast-like surface, acetone smoothing can be used…

ADVANTAGES

DISADVANTAGES

Heat and UV resistant

Bad smell

Soluble in acetone (easy post-processing)

High level of warping

Can be vapor smoothed

● Nozzle temperature:

270 - 280 °C

55

Summary of Contents for Original Prusa i3 MK2S 1.75mm

Page 1: ......

Page 25: ...Pict 11 Probe response diagram Now you are done 25 ...

Page 61: ...Pict 35 Nozzle change 61 ...