PS Engineering Inc. ®

PAR200A Audio Selector Panel, COM radio Controller and Intercom System

Installation and Operator’s Manual

200-228-0200

Page 2-3

Rev. 4, DEC. 2017

frame that are detected by the audio system. Follow the wiring diagram very carefully to help ensure a min-

imum of ground loop potential. Use only Mil Spec shielded wires (MIL-C-275000, or better). Under no

circumstances, combine a microphone and headphone wiring into the same shielded bundle. Always use a 2-

or 3-conductor, shield wire as shown on the installation-wiring diagram.

The shields can be daisy-chained together, and then connected to the ground lugs mounted on the center of

the back plate.

Radiated signals can be a factor when low-level microphone signals are "bundled" with current carrying

power wires. Keep these cables physically separated. It is very important that you use insulated washers to

isolate the ground return path from the airframe to

all

headphone and microphone jacks.

2.4.1.1

Music Inputs and Noise

PAR200A units utilize differential music inputs to help prevent noise from entering the music system. This

feature is usually transparent to the installer; however, it is important that the appropriate music signal and

ground connections are made directly to the dedicated music signal and ground inputs on the PAR200A. The

power for IFE and audio panel should be a common bus.

If a music jack is installed for Music 1 or 2, we strongly recommend isolating the jack from airframe ground,

by using an insulated mounting plate.

NOTE

Adding a high-performance audio control system, particularly in conjunction with high-performance active

noise canceling headsets, cannot improve on older avionics that were designed for cabin-speaker use. PS

Engineering makes no claim that the audio panel will provide a noise-free audio quality under all installation

conditions, particularly with older avionics.

2.4.2

Audio Panel Tray and Connector Assembly

The rack connectors mate with two 44-pin connectors in the PAR200A. The connectors are a sub-miniature

crimp-type, and require the use a hand crimp tool, from table below (or equiv.). The connectors are mounted

to the tray back plate with #4-40 screws (475-440-1038), from the inside of the tray and the mounting block,

431-891-0100. Ensure that proper strain relief and chafing precautions are made during wiring and installa-

tion, using the cable clamp (625-001-0002).

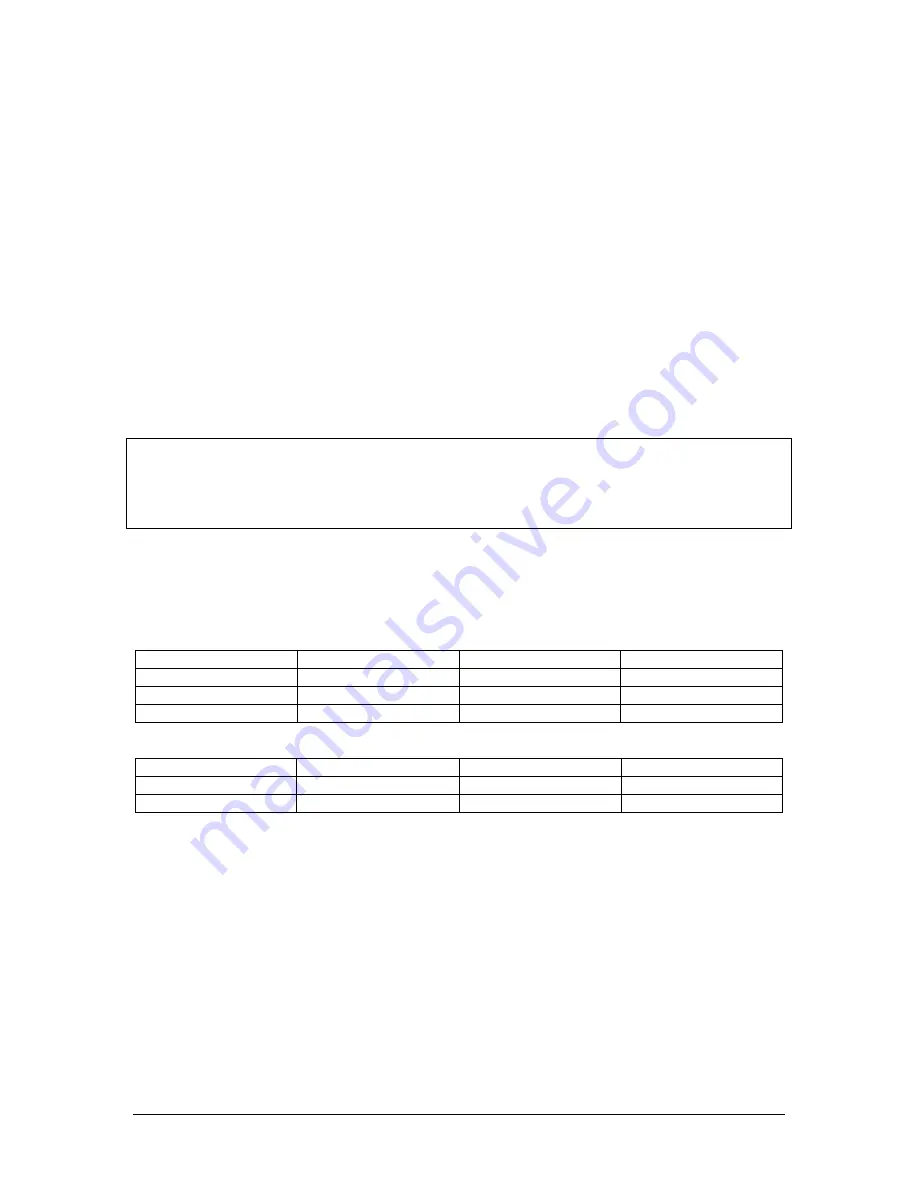

Manufacturer

Crimping Tool

Positioner

Extraction tool

AMP

601966-1

601966-6

91067-1

Daniels

AFM8

K42

M24308-1

ITT-Cannon

995-0001-584

995-0001-739

91067-1

Table 2-1 PAR200A Connector Pin crimping tools

Manufacturer

Crimping Tool

Positioner

Extraction tool

Mil-Spec

M22520/2-01

M22520/2-08

Daniels

AFM8

K13-2

Table 2-2 TY91/92 Connector Crimping tools

2.4.3

Audio Panel interface

The PAR200A is designed to interface with standard aircraft avionics, and presents a 500

receiver imped-

ance. For best results, a twisted-shielded cable is recommended from the avionics audio source to the audio

panel, with the shield grounded at the audio panel end.

Inputs N1 and N2 can be used to control navigation receiver audio, J1 Pins 17 WRT 18 and J1 19 WRT 20,

respectively.

Some avionics do not provide a separate audio low, and may introduce additional electrical noise into the

system. For best results, connect the audio low from the audio panel to the radio ground, using one conductor

of the twisted-shielded cable.