PS Engineering Inc. ®

PAR200A Audio Selector Panel, COM radio Controller and Intercom System

Installation and Operator’s Manual

200-228-0200

Appendix E

Rev. 4, DEC. 2017

Appendix E – Instructions for FAA Form 337 and continuing air-

worthiness

9.1 Instructions for FAA Form 337, Audio Panels

One method of airworthiness approval is through an FAA Form 337,

Major Repair and Alteration (Airframe, Powerplant, Propel-

ler, or Appliance)

In the case of the PAR200A, you may use the following text as a guide.

Installed audio selector and 6-place intercom, PS Engineering PAR200A, part number 050-228-(XXXX) in (

location

) at

station . Installed per

AC43.13-2B, Chapter 2, paragraph 23

(Instrument Panel Mounting). Installed per PS Engineering

Installation Operators Manual

p/n 200-228-(XXXX), revision (), dated ( ).

These units are FAA-Approved under TSO C139 for audio amplifiers, and a partial TSO C169a for communications trans-

ceivers, and meets appropriate environmental qualifications outlined in RTCA DO-160G as appropriate for this aircraft.

Interface to existing aircraft radios in accordance with installation manual and in compliance with practices listed in

AC43.13-2B

, Chapter 2. All wires are Mil-Spec 22759 or 27500. Connection to aircraft dimmer bus is

____________________. Power is supplied to the unit through a 3A circuit breaker (type and part number), and total elec-

trical load does not exceed % of the electrical system capacity with the PAR200A added.

Aircraft equipment list, weights and balance amended. Compass compensation checked. A copy of the operation instruc-

tions, contained in PS Engineering document 202-228-( ), revision ( ), dated ( ), is placed in the aircraft records. All work

accomplished listed on Work Order

.

9.2 Instructions for Continuing Airworthiness, Audio System

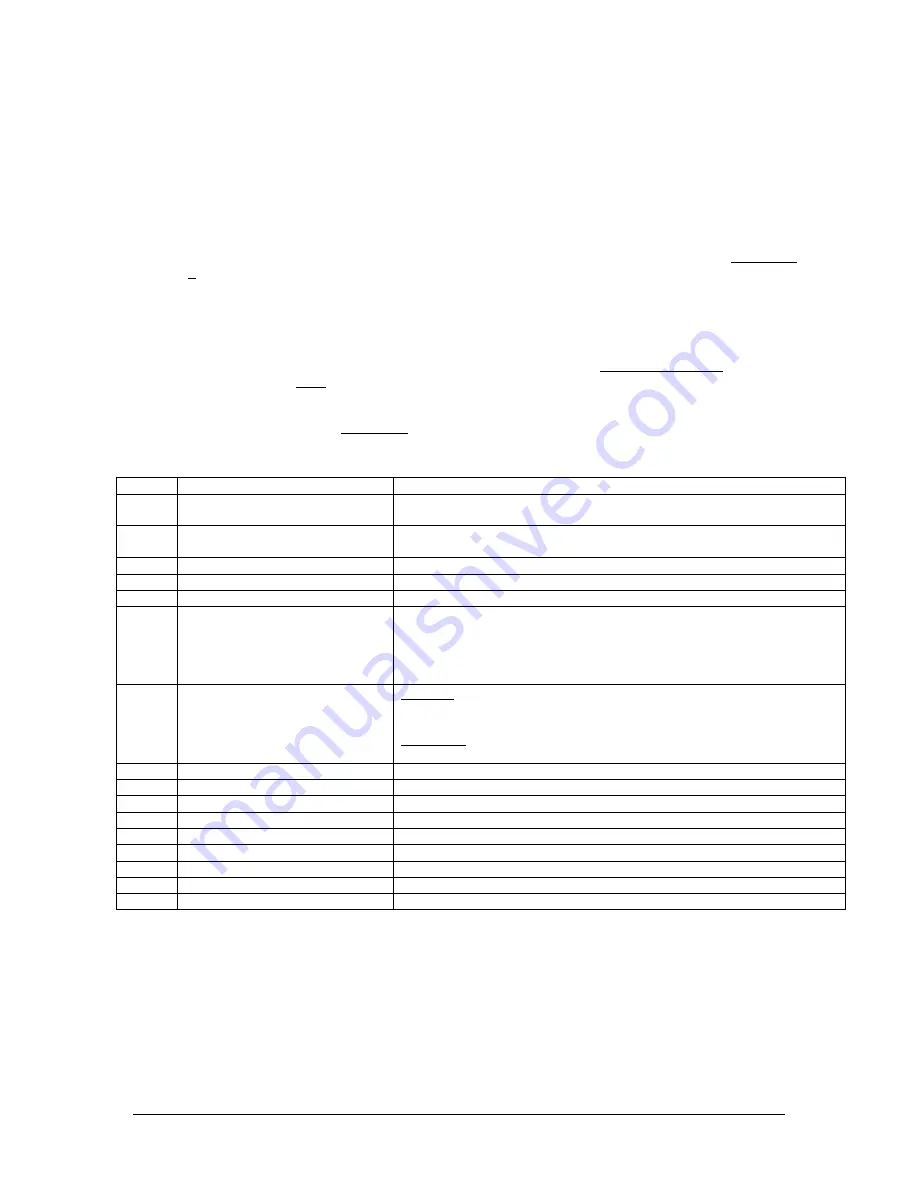

Sample ICA Checklist for PS Engineering Audio System:

Section

Item

Information

1

Introduction

Installation of audio control panel with integrated VHF communications con-

troller and intercommunications system.

2

Description

Installation as described in manufacturer’s installation manual referenced on

FAA Form 337, including interface with other avionics audio as required.

3

Controls

See installation and operator’s guide referenced on FAA Form 337.

4

Servicing

None Required

5

Maintenance Instructions

On Condition, no special instructions

6

Troubleshooting

In the event of a unit problem, place the unit into “off,” “fail-safe” and/or

“emergency” mode. This allows pilot communications using COM 1. Follow

checkout instructions in the installation manual referenced on the FAA Form

337. For a specific unit fault, contact the manufacturer at (865) 988-9800 for

special instructions.

7

Removal and replacement infor-

mation

Removal: Using a 3/32” Allen-head wrench, carefully unscrew the locking

screw located in the center of the unit. While turning the wrench CCW, gently

pull on the EDGES of the bezel until the unit is free from the mounting tray.

Installation: Engage the locking screw at the back. Turn the locking screw CW,

while applying slight pressure to the edges of the bezel. Do not over tighten!

8

Diagrams

Not applicable

9

Special Inspection Requirements

Not Applicable

10

Protective Treatments

Not Applicable

11

Structural Data

Not Applicable

12

Special Tools

None

13

Not Applicable

Not Applicable

14

Recommended Overhaul Periods

None

15

Airworthiness Limitations

Not Applicable

16

Revision

To be determined by installer

9.3 ICA for Trig TY91/92 Radio:

Other than for periodic functional checks required by the regulations, the TY91/TY92 VHF radio has been designed

and manufactured to allow “on condition maintenance”. This means that there are no periodic service requirements

necessary to maintain continued airworthiness, and no maintenance is required until the equipment does not properly

perform its intended function. When service is required, a complete performance test should be accomplished fol-

lowing any repair action. Repairs should only be carried out in accordance with Trig Avionics Limited service pro-

cedures.