13/22

NT 1401-X00 10 18 B200 Flow Control e

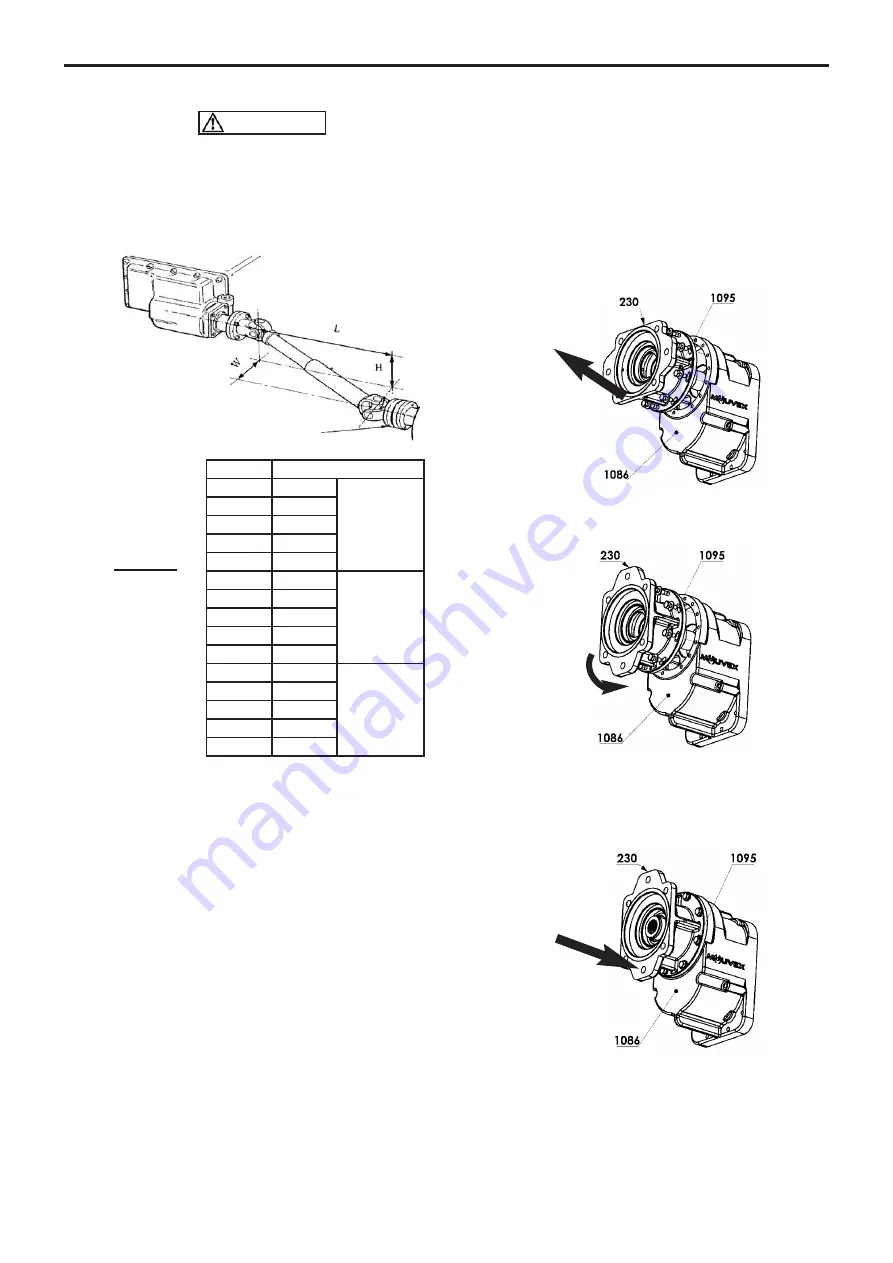

The non balancing of the drive shafts can lead to

mechanical ruptures that are susceptible of causing

important property damage and/or serious injuries.

• The drive shaft and compressor shaft MUST be parallel

within 1° and have a maximum of 10°compound misali-

gnment. See Table :

• Universal joints MUST be in phase, with the drive shaft

slip joint at mid-position. Use an even number of uni-

versal joints.

• Make sure that the compressor rotates in the direction

of the arrow on the body.

The B200 compressors fitted with a check valve can

withstand a short operating time (less than 30

seconds) in the opposite direction, as required for

checking the rotation direction.

NOTICE :

Prolonged operation in a direction different from the

direction indicated on the drawing below may cause

serious damage to the compressor and would cancel the

warranty.

3.3 B200 HY with hydraulic motor

The B200 HY compressors have a female splined shaft

ANSI B92-1a that allows to flange directly on hydraulic

motor epuipped with a shaft 13T 718 SAE 16/32 and a

mounting flange SAE B 2 or 4 holes.

3.3.1 Hydraulic motor assembly

It is possible to change the orientation of the lantern

230

,

taking care to proceed as follows :

• Loosen and remove the 8 screws

1095

.

• Rotate the lantern

230

so as to offset the ports and

move them over the set of tapped holes on casing

1086

that approach the desired position.

• Make sure that at least one of the 2 collectors is loca-

ted in the lower part of the lantern

230

, otherwise turn

the lantern 230 by 180°.

• Engage the lantern

230

.

• Tighten the 8 screws

1095

.

A

Universal joint angle

0,017

1°

VERY GOOD

0,035

2°

0,052

3°

0,070

4°

0,087

5°

0,105

6°

GOOD

0,125

7°

0,141

8°

0,158

9°

0,176

10°

0,194

11°

LIMIT

VALUES

0,213

12°

0,231

13°

0,249

14°

0,268

15°

_________

A =

√

H² + W²

L

If H = Zero, A = W / L

If W = Zero, A = H / L

CAUTION

3. INSTALLATION (continued)