14/22

NT 1401-X00 10 18 B200 Flow Control e

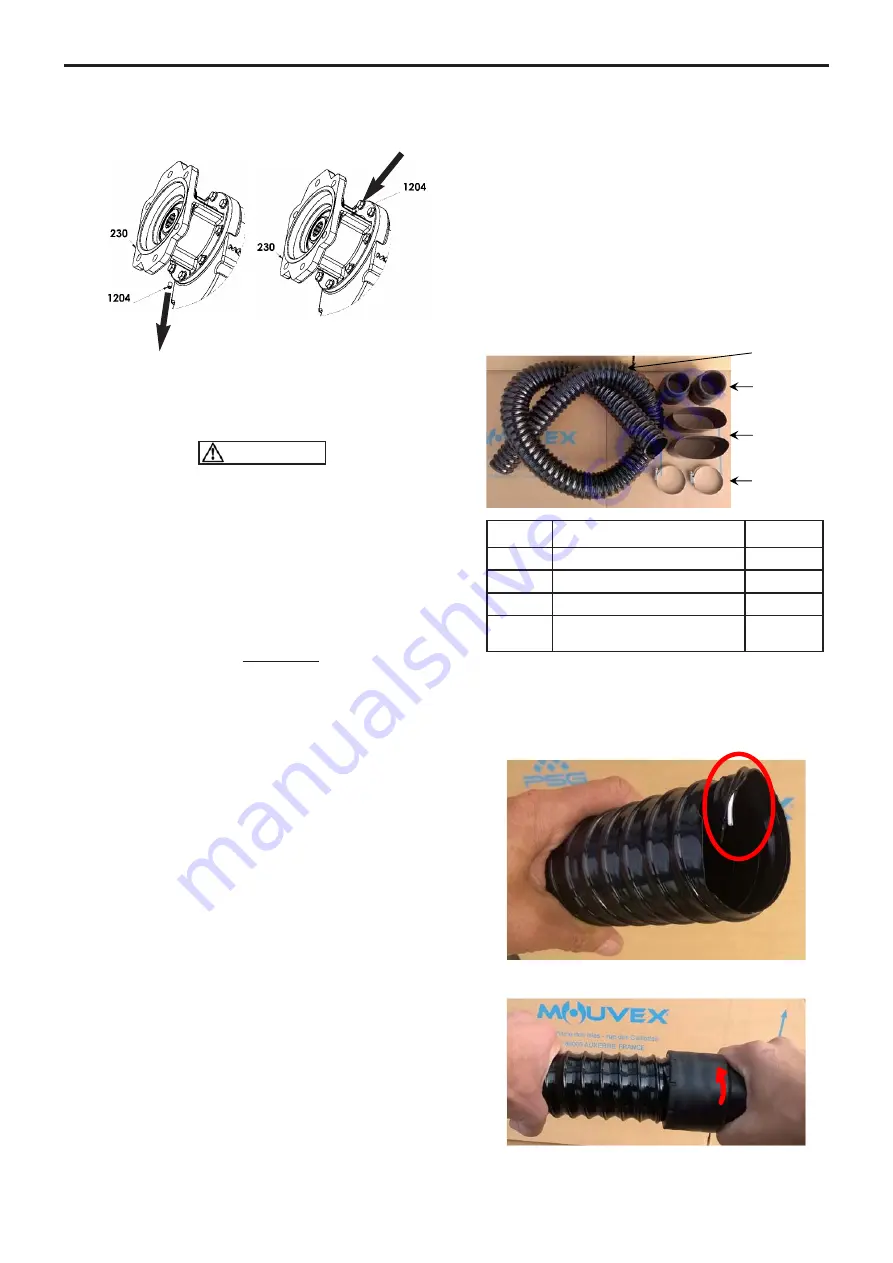

• Install the screwing plug

1204

in the highest collector

on the lantern

230

.

• Check that the rotation direction of the motor and the

compressor are correct.

• Lubricate the motor shaft and the female splined shaft

1091

to facilitate subsequent disassembly.

Screws

1095

must be :

• equipped with their lock washers, notches on the

side of the screw head,

• sealed with Loctite

®

* thread locking 243 or equivalent,

• tightened at 13 Nm.

3.3.2 Adjustment of the drive speed

See § ADJUSTMENT OF THE DRIVE SPEED.

3.3.3 Motor management

The Motor management is mandatory, it has to ensure 2

missions :

•

To secure the operating range :

The operating point

(otherwise the range) must be set to avoid any ope-

ration outside the range. If a risk remains (need to

switch in complement a gear box button) an infor-

mation sticker shall be affixed in the cabin.

•

To ensure a smooth start-up :

The start-up of the

PTO must be carried out gradually without genera-

ting a peak of torque to avoid damaging the

Compressor. This is particularly sensitive for the

B200 PF which is equipped with a shaft groove.

It is in particular to ensure that the parameter

‘’TRANSMISSION INPUT SPEED’’ (N° 10.520 on

MERCEDES) is set to a value less than 10.

Otherwise, that will generate in a medium term a

breakage of the B200 shaft.

3.4 Piping

3.4.1 Inlet

The suction side of the compressor MUST be fitted with

an adequately sized air filter, which MUST be protected

from water, road spray, or other debris. This filter is avai-

lable from MOUVEX. Use of wrong filter will void warran-

ty. The compressor filter must be connected by means of

a hose capable of operating in vacuum and of a sufficient

length to absorb the relative movements of the compressor

relative to the chassis. The compressor is delivered with

an inlet connection kit which is installed as follows :

Composition of the kit :

Assembling procedure :

• To cut the hose to the length requested.

• To fold back the end of the wire inside.

• To screw home the humps at the 2 ends.

16

4

884

152A

165-166

Item

Description

Quantity

152A

Heat shrinkable sleeve

2

164

Hose

1

165-166

Clamp

2

884

Hump

1XØ50

1XØ57

CAUTION

3. INSTALLATION (continued)

*

Loctite

®

is a registered trademark.