16/22

NT 1401-X00 10 18 B200 Flow Control e

Top view

Installation rules : Discharge line

All the connections must be welded and be the object

of a waterproof quality control.

During installation, position a pressure gage on the com-

pressor output, so as to measure the operating pressure.

The measurement should be done at the discharge flange

level and should not exceed 2,5 bar over the allowable

operating range of the compressor.

It is mandatory to protect the compressor with the Check

relief valve supplied by MOUVEX. The check valve pre-

vents any air from returning in the compressor when it is

no longer in operation.

The safety valve protects the compressor against possi-

ble overpressure. The maximum set point of the valve is

2,5 bar.

If there is a drop in pressure between the pres-

sure relief valve and the compressor, reduce the pres-

sure relief valve setting by the value of the pressure

drop.

It is the installor responsability to check that the

relief valve is compliant with the compressor performance

for the application speed.

The compressor is delivered with a check and relief valve

allowing 3 settings capabilities : 2 bar, 2,3 bar or 2,5 bar.

It will have to be selected depending of the installation limits

and by making sure the maximum pressure of 2,5 bar of

the compressor is never exceeded. Be careful in particular

with the pressure drop located between the check relief

valve and the compressor especially if an air cooler and

a silencer are used.

It is forbidden to insert a damping valve in the pipe lin-

king the compressor to the tank hose connector in order

to avoid any risk of water entering.

Ensure that ALL components are capable of operation at

the maximum system pressure limits and that all vessels

are adequately protected by SEPARATE relief valves.

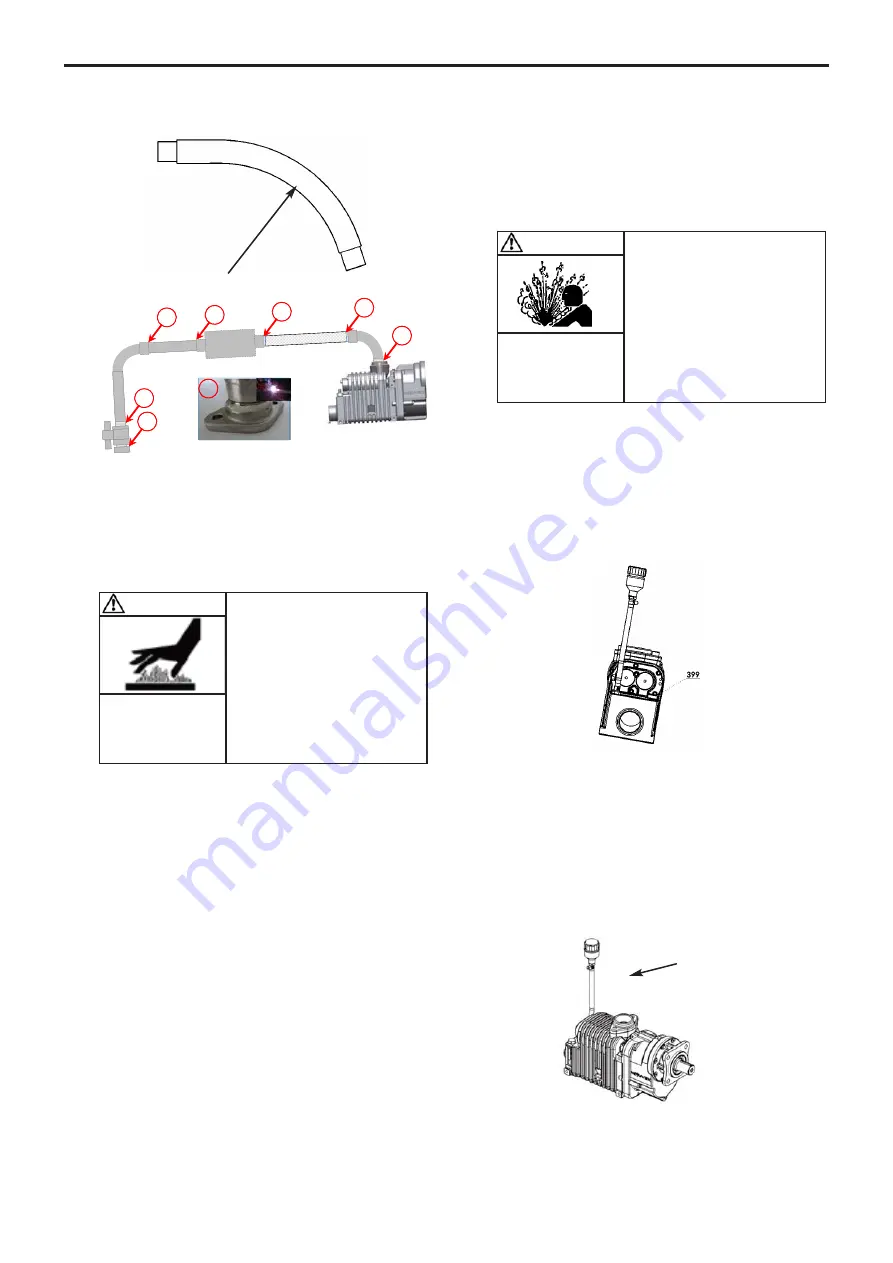

3.4.3 Oil breather

Compressor B200 is fitted with an oil breather which is

mounted on a hose for easier installation.

In case of the inclination of the compressor, it is essen-

tial to position the breather on the highest tapped hole.

Invert the positions of the oil gage

399

and the breather

assembly, as appropriate.

Position the breather plug in a clear area, to avoid any oil

condensation.

Do not crush the hose when positioning the breather, so

as to allow any oil vapors to be evacuated.

The hose mustn’t be shortened,, keeps imperatively its

original length.

The breather must be placed above the compressor,

preferably with the connecting hose running up towards

the breather.

1

1

1

1

1

1

1

1

CRV

Option

silencer

Hose (B200PF)

Oil breather

}

R mini 50 cm

WARNING

FAILURE TO INSTALL ADEQUATELY

SIZED PRESSURE RELIEF VALVE(S)

CAN CAUSE PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

Hazardous pressure

can cause

personal injury

or property damage.

CAUTION

OPERATING A COMPRESSOR ABOVE

ITS MAXIMUM OPERATING PRESSURE

CAN CAUSE SUBSTANTIAL PROPERTY

DAMAGE OR SERIOUS BODILY INJU-

RIES.

Extreme heat can

cause injury or

property damage.

3. INSTALLATION (continued)