20/22

NT 1401-X00 10 18 B200 Flow Control e

7.1 Compressor

The equipment must be systematically stored in an area

sheltered from bad weather.

The equipment must bear its original protective compo-

nents until it is installed in its final application.

If installation is interrupted, put back in place the original

protective components or equivalent components.

7.2 BSC2 oil

In its unopened original container in a dry, frost-free and

light-free place.

The maximum shelf life is approx. 60 months.

7. STORAGE CONDITIONS

The compressor must be scrapped in compliance with the

regulations in force.

During this operation, particular care must be paid to the drai-

nage stages of the compressor.

8. SCRAPPING

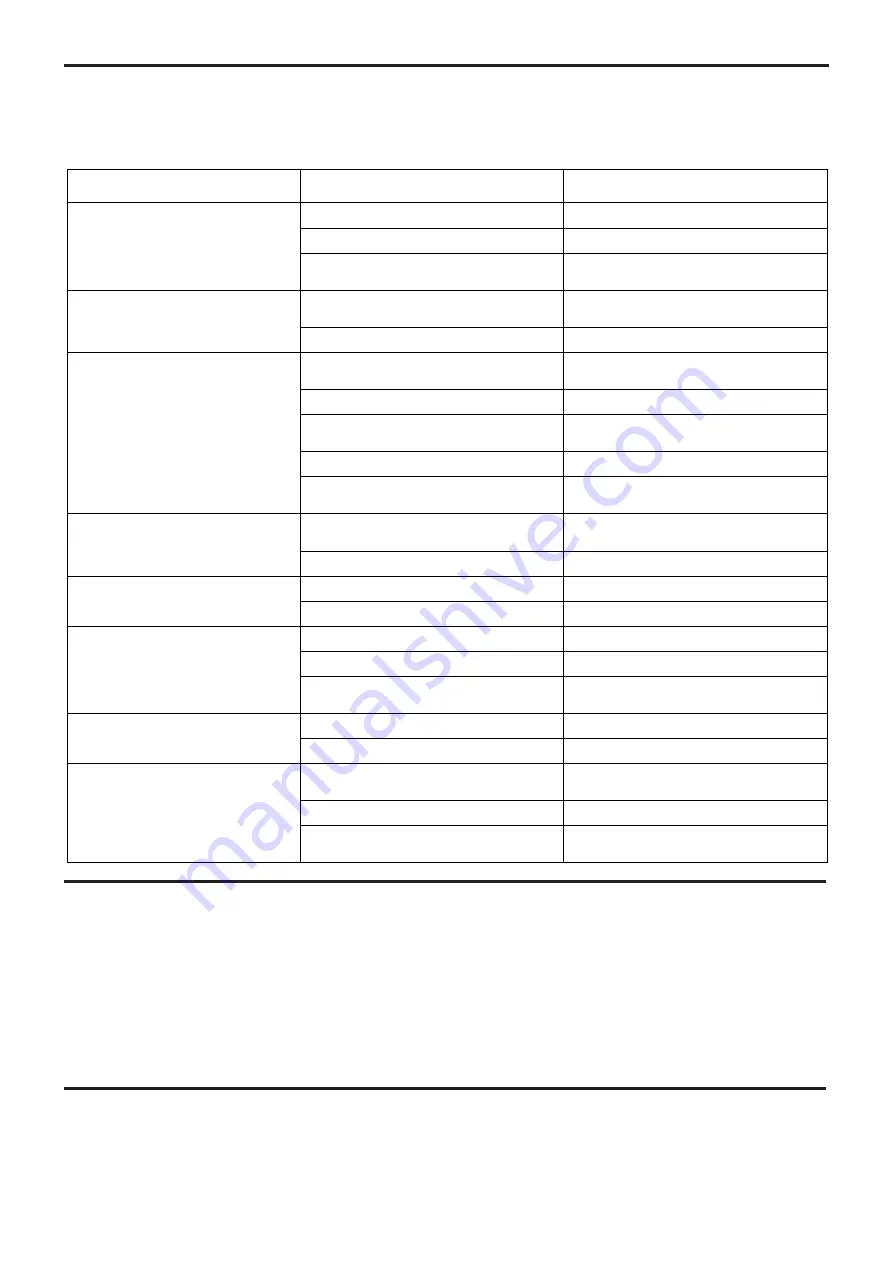

Problem

Possible

ori

g

in

Possible

solution

1.

P

ressure

issue

T

oo

much

pressure

drop.

T

o

chec

k

pipes

diameter.

Relief

v

al

v

e

dama

g

ed.

T

o

chec

k

the

openin

g

point.

N

o

return

v

al

v

e

dama

g

ed.

T

o

chec

k

the

proper

operatin

g

of

the

N

o

return

v

al

v

e.

2.

F

lo

w

rate

issue

W

ron

g

Compressor

speed.

T

o

ad

j

ust

the

speed

b

y

ta

k

in

g

care

of

the

ran

g

e

allo

w

ed.

Relief

v

al

v

e

dama

g

ed.

T

o

chec

k

the

openin

g

point.

3

.

Abnormal

hi

g

h

temperature

Air

filter

clo

gg

ed.

T

o

clean

the

cartrid

g

e

or

to

replace

it.

Air

pressure

too

much

hi

g

h.

T

o

see

problems

1.

/

2.

Outside

temperature

too

much

hi

g

h.

T

o

respect

the

ma

x

imum

e

x

ternal

temperature

allo

w

ed.

L

ac

k

of

oil.

T

o

chec

k

the

oil

le

v

el.

Compressor

speed

too

much

lo

w

.

T

o

ad

j

ust

the

speed

b

y

ta

k

in

g

care

of

the

ran

g

e

allo

w

ed.

4.

Inlet

pressure

drop

> 7

5

mbar

(

Clo

gg

in

g

indicator

red

)

Air

filter

clo

gg

ed.

T

o

clean

the

cartrid

g

e

or

to

replace

it.

Air

inlet

hose

folded.

T

o

chec

k

the

air

inlet

hose.

5.

Compressor

doesn

’

t

operate

T

or

q

ue

limiter

dama

g

ed.

T

o

replace

the

tor

q

ue

limiter.

T

ransmission

dama

g

ed.

T

o

consult

y

our

Ser

v

ice

point.

6.

T

or

q

ue

limiter

dama

g

ed

Scre

w

Compressor

dama

g

ed.

T

o

consult

y

our

Ser

v

ice

point.

W

ron

g

motor

/

transmission

mana

g

ement.

T

o

consult

y

our

T

ruc

k

dealer.

Oil

too

much

v

iscous.

T

o

be

in

compliance

w

ith

the

MO

U

V

EX

Instructions.

7

.

Oil

lea

k

T

oo

much

oil.

T

o

chec

k

the

oil

le

v

el.

Oil

breather

clo

gg

ed.

T

o

clean

the

oil

breather.

8.

Vibrations

W

ron

g

motor

speed.

T

o

increase

the

speed

b

y

ta

k

in

g

care

of

the

ran

g

e

allo

w

ed.

T

ransmission

dama

g

ed.

T

o

chec

k

the

dri

v

in

g

shaft.

L

ac

k

of

ri

g

idit

y

of

the

chassis.

T

o

be

in

compliance

w

ith

the

T

ruc

k

Manufacturer

Instructions.

6. TROUBLESHOOTING

CAUTION :

OBSERVE ALL SAFETY WARNINGS CONTAINED IN THIS MANUAL.