21/22

NT 1401-X00 10 18 B200 Flow Control e

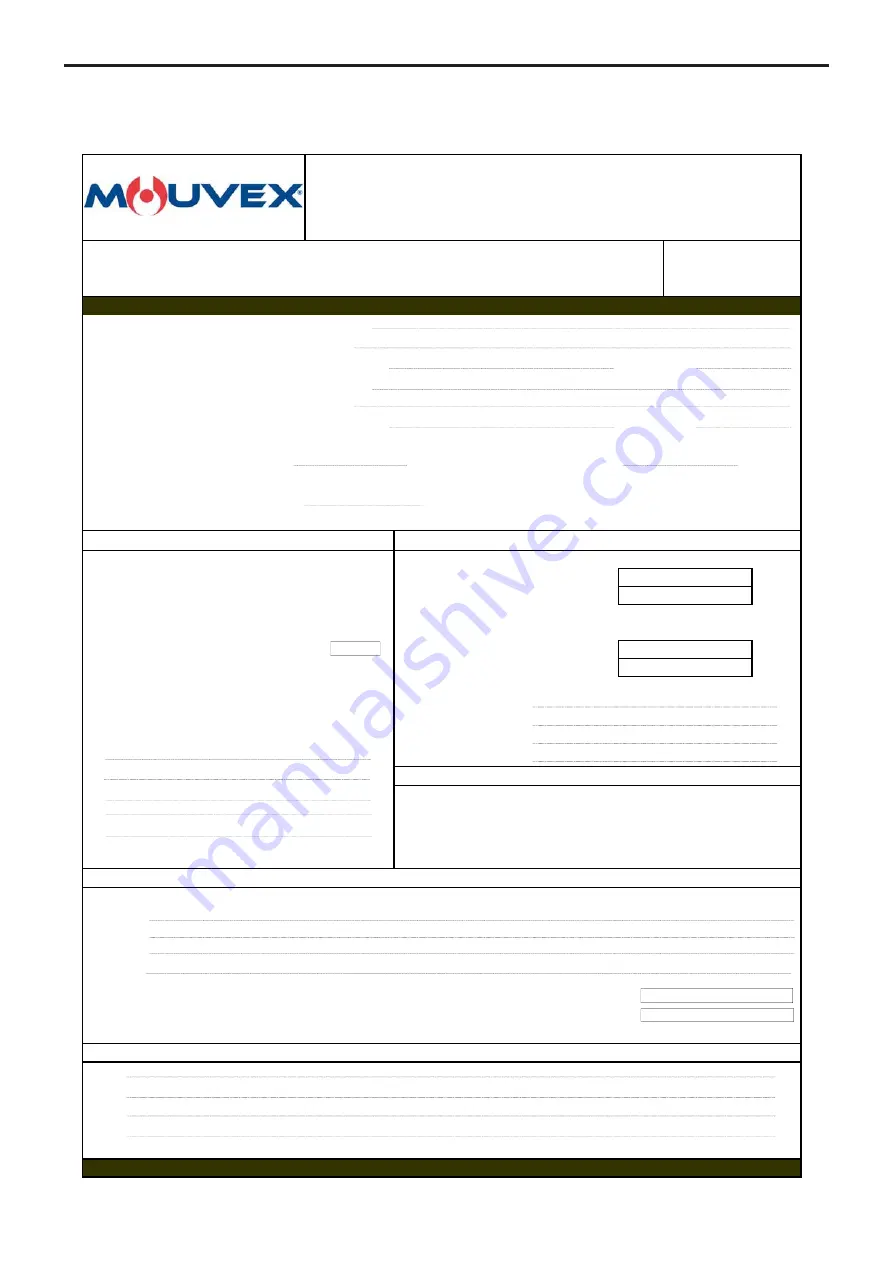

9. COMPRESSORS FORM INFORMATION

Before any material return, it is required to get an authorization from MOUVEX.

MO

U

V

EX

After

Sales

D

epartment

Tel

:

(33)

3

86

4

9

86

03

D

ate

:

Z

.I.

La

Plaine

des

Isles

Fax

:

(33)

3

86

4

9

86

48

Followed

by

:

8

9

000

AUXERRE

-

FRANCE

File

:

A

– N

a

me

and

address

o

f

user

Person

to

contact

:

Phone

Nr

:

B

– N

ame

and

address

o

f

installator

Person

to

contact

:

Phone

Nr

:

C

-

M

aterial

'

s

serial

number

D

-

S

tarting

up

date

Running

time

estimation

hours

PTO

flanged

Propshaft

drive

system

(direct

PTO

drive)

Compressor

'

s

speed

30R

20R

1

9

R

13R

22L

15L

Operating

pressure

12R

10L

Torque

limiter

Pressure

relief

valve

setting

(value)

B

elt

drive

system

PTO

ratio

Package

air

cooler

Package

RTI

Product

transfered

Air

connection

on

truck

chimney

D

irect

air

connection

Flexible

pipe

between

filter

and

compressor

Inox

pipe

between

filter

and

compressor

B

locking

Leakage

Noise

,

vibration

Other

I

-

H

as

the

machine

been

replaced

by

a

new

one

?

If

yes

which

is

the

serial

number

J

-

H

as

the

machine

been

replaced

by

a

renoved

one

?

If

yes

which

is

the

serial

number

r

év.16/10/2013

Please

send

us

bac

k

this

completed

f

orm

b

y f

a

x

or

E

as

quic

k

as

possible

.

G

-

S

uction

conditions

H

-

D

ES

CR

I

P

TION O

F

THE

FA

ILU

R

E

K

-

Remar

k

s

and

comments

o

f

the

user

about

the

problem

:

I

n

order

to

properl

y

deal

with

the

return

material,

please

f

ill

in

this

f

orm

.

E

-

I

nstallation

details

F

-

O

perating

parameters

C

OM

PR

ESSO

R

S

F

O

R

M IN

F

O

R

M

A

TION

Other

(electric

,

thermic

or

hydraulic

motor)

Motor

speed

(tachometer)

at

the

time

of

the

incident