61

CADDY WOOD/ELECTRIC

8

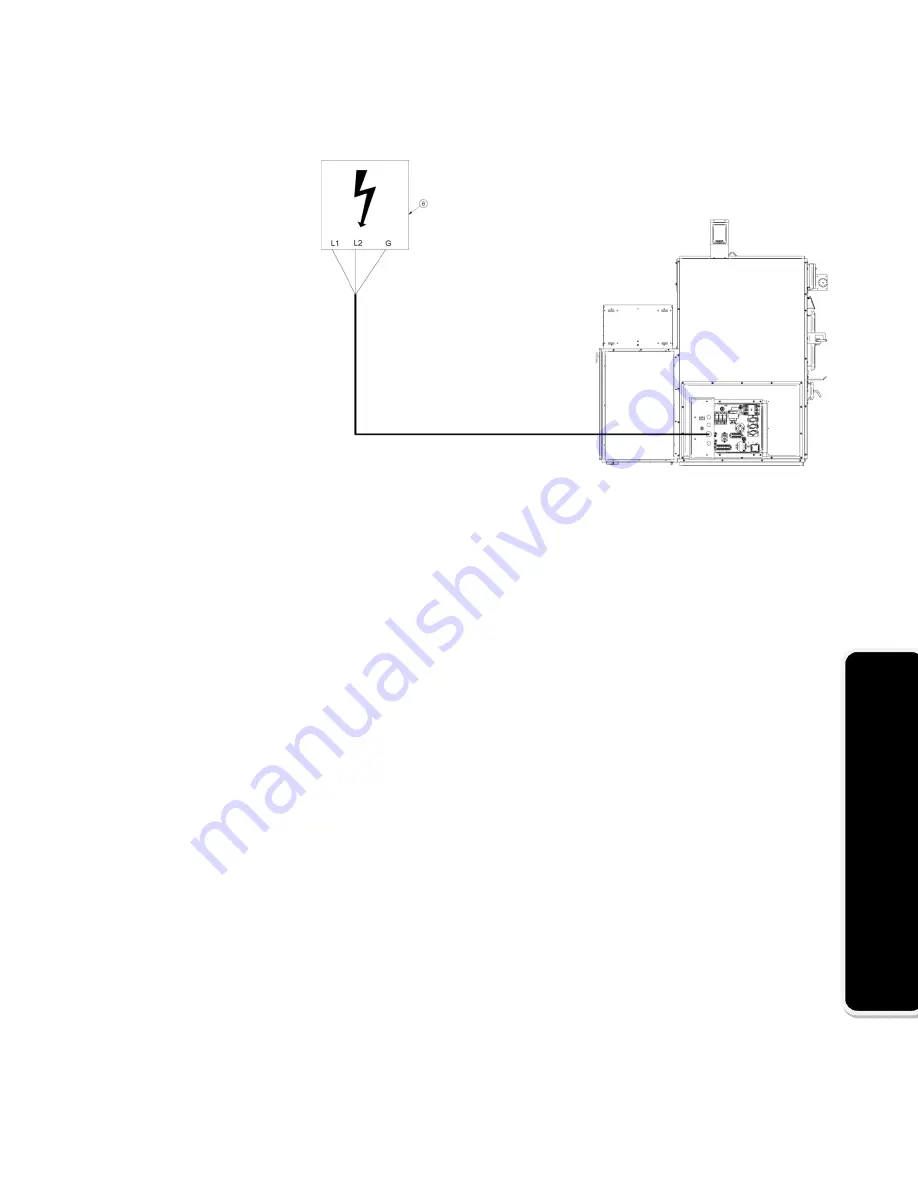

Using a flat

screwdriver, remove

the largest knockout

located on the left

access panel of the

electric element.

Run the feeder cable

(not supplied) from

the house main

entrance (6) through

the opening made in

the left access

panel.

Note: Refer to electrical diagram included with the electrical element for wiring.

Summary of Contents for Caddy PF01010

Page 16: ...16 CADDY ADD ON Installation Instructions CADDY WOOD ADD ON PF01010 PA08522 ...

Page 22: ...22 CADDY ADD ON Example 1 Example 2 ...

Page 24: ...24 CADDY ADD ON Figure 3 1 4 3 a ...

Page 30: ...30 CADDY ADD ON ...

Page 40: ...40 CADDY WOOD ONLY ...

Page 42: ...42 CADDY WOOD ONLY Figure 3 2 2 3 a ...

Page 52: ...52 CADDY WOOD ELECTRIC Figure 3 3 3 3 a ...

Page 55: ...55 CADDY WOOD ELECTRIC OUTSIDE VIEW OF THE ELECTRIC UNIT ...

Page 68: ...68 Figure 3 4 4 3 a ...

Page 70: ...70 ...

Page 73: ...73 Wiring diagram for Riello Burner ...