8

PIPE CONNECTOR AND DAMPER

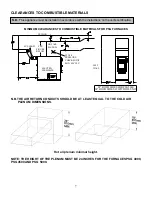

A 6” diameter chimney listed for use with wood burning heating appliances is recommended for the PSG2000, 7” for

PSG3000-4000 and 8” for the others models. If draft exceed -0.06 w.c., you must install a barometric control (see

Damper).

Never install a manual damper.

For a proper installation, follow the advices below:

1. All the joints of the evacuation pipe must be secured, using three screws.

Make sure that each screw goes through the inner walls of both connectors (male and female). See

pictures below showing a male-female coupling.

2. A minimum rise of 1/4 inch per horizontal foot must be respected.

Before proceeding to connection, remove all accessories such as:

scraper, shovel and poker from the evacuation pipe of the furnace.

PROPER INSTALLATION

UNPROPER INSTALLATION

OIL FLUE

PIPE

(OPTION)

MAIN

COLLECTOR

CAUSE RESTRICTION

24” both sides for

PSG5000

WOOD

FLUE

PIPE