Features

• Powerful motor blower unit has a proven flawless performance record

• 1/2- micron filter cartridge for fine filtration

• Captures over 99% of the dust and debris before it passes through the motor blower

• Includes dolly with locking casters and 35 gallon fiber drum

• Easy cleaning of debris from the collection canister

• With nearly clean filters, system consistently runs at peak performance

• Aluminum impeller providing superior performance

• “Neutral vane” intake maximizes airflow

• Longer cyclone funnel improves separation efficiency

• Includes convenient heavy-duty on/off switch on power cord

• Only 85” high — fits through most doorways

• Includes built-in re-circulation system — no need for filter cleanout container

Contents

Box #1 – Motor Blower and Housing

Box #2 – Cyclone Cone

Box #3 – Stand with Base

Box #4 – Fiber Drum with Recirculating Kit

Box #5 – Filter Cartridge

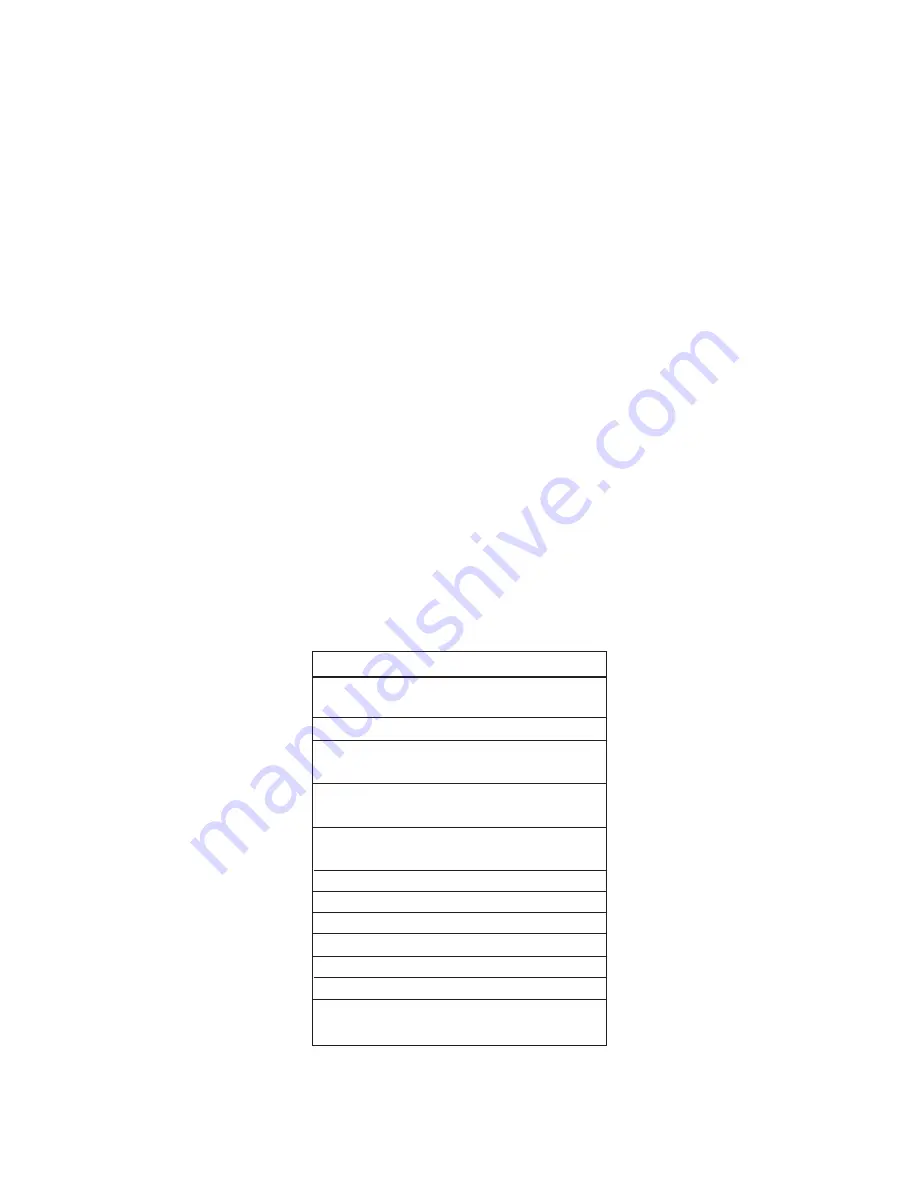

Specifications

Motor

2.0 HP, 9 Amps

3450 RPM

Impeller

14” Aluminum

Max. Air Flow

1025 CFM

(through cyclone)

Filter Cartridge

36” x 14” OD

350 sq. ft. filter area

Filter Cleanout Drum

N/A - unit uses re-circulating cleanout

Debris Drum

35 gallon

Height (on drum)

85”

Weight

200 lbs.

Sound Rating

76db

Air Inlet Diameter

6”

Dust outlet to Filter

6”

Footprint

27-1/2” x 21-1/4”

(stand base)