PSI Waste Equipment Services, Inc.

P50 Apartment Compactor

Sec

Ɵ

on 5, Maintenance

14

Preventa

Ɵ

ve Maintenance

Each

Container

Change

Make

sure

all

control

bu ons,

door

interlocks,

and

warning

light

and

alarm

work

properly.

Listen

to

compactor.

It

should

run

quietly

and

smoothly.

Make

sure

container

ratchet

and

latch

operate

smoothly.

Look

for

obvious

oil

leaks

or

unsafe

condi ons.

Correct

devia ons

before

pu ng

the

compactor

back

in

service.

Monthly

Or

More

Frequently

As

Needed

Grease

charge

box

fl

oor,

walls,

and

slider

plate

track

to

prevent

premature

wear

and

to

keep

unit

running

smooth

and

quiet.

Wipe

photo

eye

clean

with

a

damp

paper

towel.

Use

soap

and

water

if

needed.

Do

not

use

sol

‐

vents

or

abrasive

materials!

Check

oil

level

using

the

dip

s ck

on

the

breather/dips ck.

With

the

ram

in

the

back

posi on,

oil

level

should

be

within

1

‐

1/2”

of

top

of

s ck.

If

more

than

1

gallon

(5/8”)

of

oil

is

being

lost

per

year,

call

a

quali

fi

ed

compactor

repair

company

and

have

them

check

the

cylinders

and

hoses

for

leaks.

Clean

trash

from

under

and

around

compactor.

Every

5

Years

Change

oil,

clean

reservoir,

clean

or

replace

suc on

screen

(inside

tank).

Make

sure

suc on

tube

is

ght.

Use

a

quality

AW46

hydraulic

oil

(8

gallons).

This

service

should

be

performed

by

quali

‐

fi

ed

technician.

For

more

informa on

on

repairs,

refer

to

our

repair

manual

at

www.psiwaste.com/P50.html

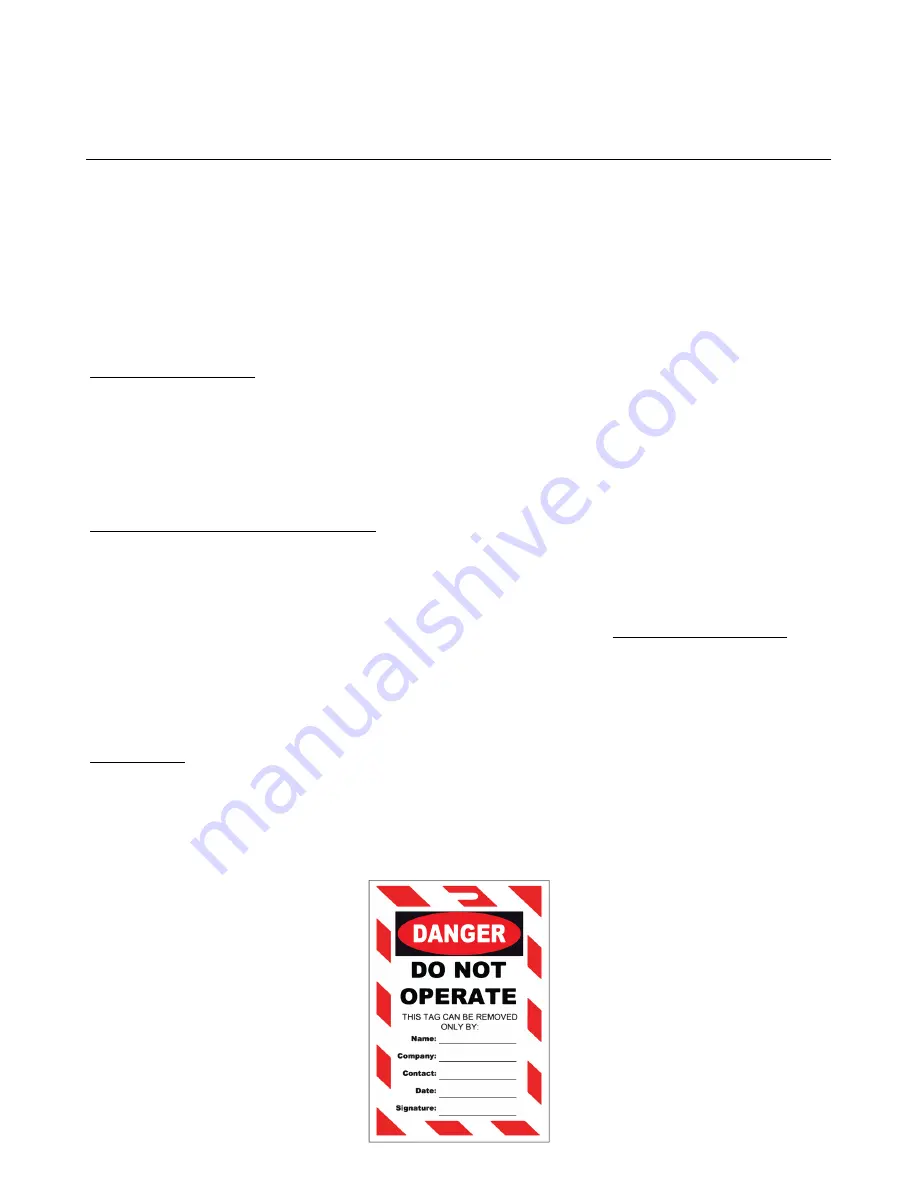

Warning:

Lockout/Tagout

before

entering

any

por on

of

compactor!

Only

quali

fi

ed

and

authorized

personnel

should

work

on

the

machine!

Your

P50

is

designed

to

last

many

years

with

li le

maintenance.

With

that

said,

it

is

prudent

to

keep

your

compactor

clean

and

dry.

Though

the

electrical

components

are

sealed

and

can

get

wet,

you

should

NOT

pressure

wash

the

panel,

photo

eye

or

other

electrical

components.

Make

sure

the

exte

‐

rior

of

the

compactor

has

a

good

coat

of

paint

on

it

and

follow

the

maintenance

schedule

below.