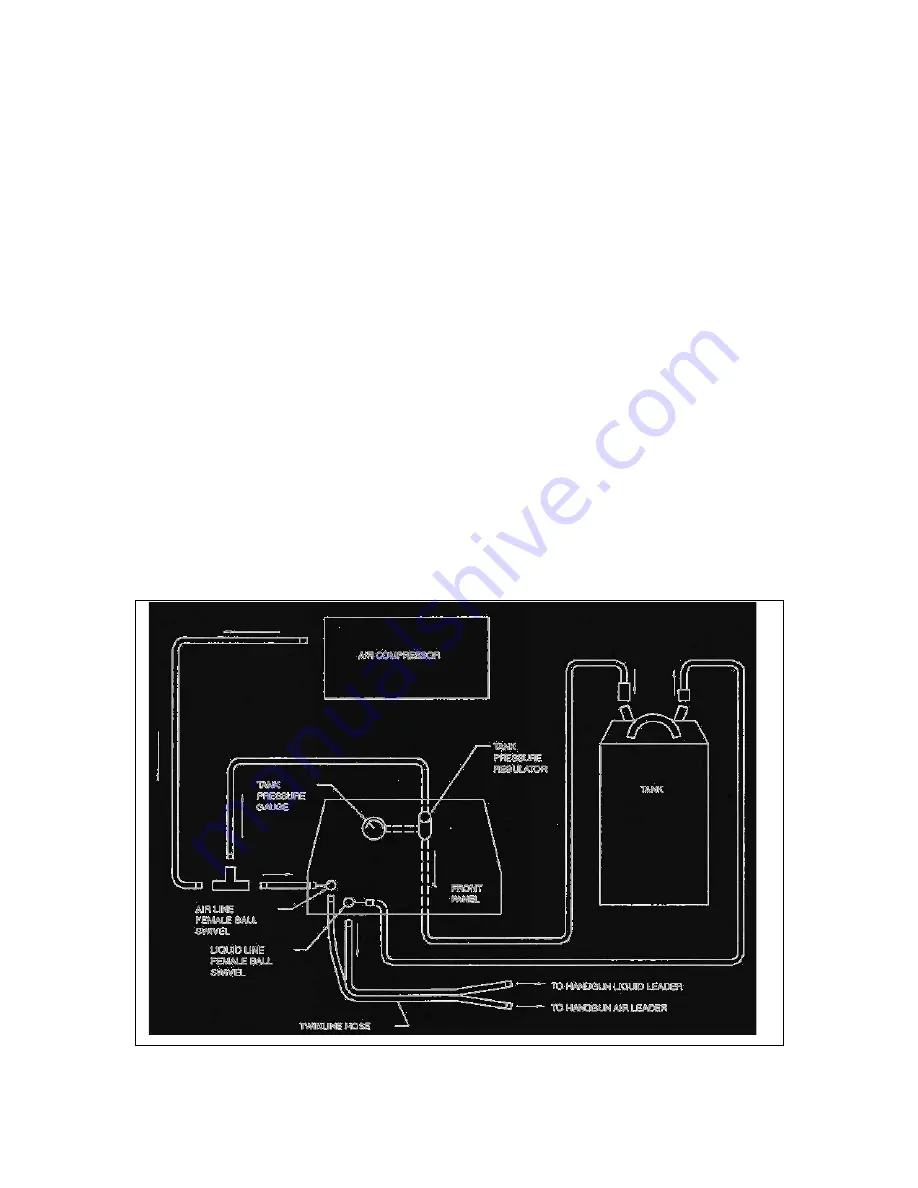

The Air & Liquid Delivery System

The Air Compressor

The air compressor produces compressed

air which atomizes and propels the liquid. It

plugs into a 110 volt electrical source. Use

the unit with an extension cord of no more

than 50 feet and rated for no less than 15

amp service. The On/Off switch is on the

side of the air compressor. The compressor

has an adjustable relief valve on the back.

It should be set between 70 and 100 psi.

The Front Panel Air Connection

The second tee routes the air to the top

¼

”

female ball swivel (FBS) fitting on the front

panel of the sprayer. The

¼

” end of the air

hose of the twinline hose connects to this

fitting. Use an 11/16” wrench on the FBS

and 9/16” wrench on the twinline hose

fitting. The other end of the twinline hose

connects to the air leader of the handgun.

The Tank Pressure Regulator

The second tee also routes air to the tank

pressure regulator. It corresponds with the

pressure gauge on the left side of the front

panel. The regulator is operated by pulling

out the dial and turning it clockwise to

increase pressure or counter-clockwise to

decrease pressure. It should be set

between 12 and 15 psi. Once the desired

pressure is achieved, push in the dial to lock

it in place.

Note:

For best results, set the pressure

from a lower pressure to a higher pressure.

If the pressure is set too high, adjust the

regulator below the desired pressure then

adjust it up to the desired pressure.

Two lines run from the tank pressure

regulator. One line runs to the tank

pressure gauge on the front panel. The

other runs to the inlet quick connect on the

tank.

Figure 2.

The Air and Liquid Delivery Systems

Summary of Contents for MAGNETspray

Page 3: ......

Page 4: ......

Page 12: ...TANK PLUMBING ASSEMBLY XT SERVICE PARTS MAIN ASSEMBLY ...

Page 14: ......

Page 15: ...HANDGUN SERVICE PARTS ...

Page 16: ......