CT10.241, CT10.241-C1

CT-Series

3-P

HASE

,

24V,

10A,

240W

May 2018 / Rev. 2.0a DS-CT10.241-EN All values are typical figures specified at 3x 400Vac, 50Hz input voltage, symmetrical

phase voltages, 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time unless otherwise noted.

www.pulspower.com Phone +49 89 9278 0 Germany

25/28

22.6.

P

ARALLEL

U

SE FOR

R

EDUNDANCY

1+1 Redundancy:

Devices can be paralleled for redundancy to gain higher system availability. Redundant systems require a certain

amount of extra power to support the load in case one device fails. The simplest way is to put two devices in parallel.

This is called a 1+1 redundancy. In case one device fails, the other one is automatically able to support the load current

without any interruption. It is essential to use a redundancy module to decouple devices from each other. This

prevents that the defective unit becomes a load for the other device and the output voltage cannot be maintained any

more.

For 1+1 redundancy the ambient temperature is not allowed to 70°C.

Recommendations for building redundant power systems:

- Use separate input fuses for each device.

- Use separate mains systems for each device whenever it is possible.

- Monitor the outputs of the individual devices. Use the DC-ok contact, which is included in the redundancy module.

- It is desirable to set the output voltages of all devices to the same value (± 100mV) or leave it at the factory setting.

- Set the devices into “Parallel Use” mode.

Pay attention that leakage current, EMI, inrush current, harmonics will increase when using multiple devices.

N+1 Redundancy:

Redundant systems for a higher power demand are usually built in a N+1 method. E.g. four devices, each rated for 10A

are paralleled to build a 30A redundant system.

Pay attention that leakage current, EMI, inrush current, harmonics will increase when using multiple devices.

Keep an installation clearance of 15mm (left / right) between two devices and avoid installing the devices on top of

each other.

Do not use devices in parallel in mounting orientations other than the standard mounting orientation or in any other

condition, where a reduction of the output current is required.

For 1+1 redundancy the ambient temperature is not allowed to 60°C.

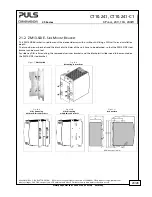

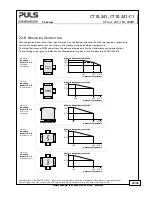

Wiring examples for 1+1 and n+1 redundancy:

Fig. 22-4

1+1 Redundant configuration for

10A load current and redundancy modules

Fig. 22-5

N+1 Redundant configuration for 30A load current with multiple power

supplies and redundancy modules

Failure

Monitor

Power

Supply

+ +

- -

L1 L2

PE

Output

Input

L3

I

I

L1

L2

I

I

PE

opt

ional

Power

Supply

+ +

- -

L1 L2

PE

Output

Input

L3

I

L3

I

YRM2.DIODE

Redundancy

Module

Output

Input

1

Input

2

+

-

+

-

+

-

o o o o

2

1

Input ok

YRM2.DIODE

Redundancy

Module

Output

Input

1

Input

2

+

-

+

-

+

-

o o o o

2

1

Input ok

Load

Failure

Monitor

Power

Supply

+ +

- -

L1 L2

PE

Output

Input

L3

I

L1

L2

I

I

PE

opt

ional

Power

Supply

+ +

- -

L1 L2

PE

Output

Input

L3

I

L3

I

YRM2.DIODE

Redundancy

Module

Output

Input

1

Input

2

+

-

+

-

+

-

o o o o

2

1

Input ok

YRM2.DIODE

Redundancy

Module

Output

Input

1

Input

2

+

-

+

-

+

-

o o o o

2

1

Input ok

Load

I I

opt

ional

Power

Supply

+ +

- -

L1 L2

PE

Output

Input

L3

I

YRM2.DIODE

Redundancy

Module

Output

Input

1

Input

2

+

-

+

-

+

-

o o o o

2

1

Input ok

I I

opt

ional

Power

Supply

+ +

- -

L1 L2

PE

Output

Input

L3

I

YRM2.DIODE

Redundancy

Module

Output

Input

1

Input

2

+

-

+

-

+

-

o o o o

2

1

Input ok

I