PULSAR MEASUREMENT

55

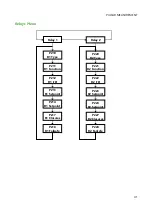

Relay Parameters

All relay related parameters are prefixed with a

2

**.

The second digit of the three-figure parameter number denotes the relay

number as follows:

2

1

* parameters for Relay 1

2

2

* parameters for Relay 2

The third digit selects specific parameters for the setting up of the relays,

which can be selected individually and results in the following parameter

numbers for each relay.

Relay 1 21

0

to 21

8

Relay 2 22

0

to 22

8

P210, P220 - Relay Type

This parameter defines what type each relay should be, see the table below

or available options.

OPTION

DESCRIPTION

0 = Not in Use (Default)

Relay not in use programmed.

1 = Alarm

Relay is programmed as an alarm relay, which

will de-energise ON, and energise OFF. This will

ensure an alarm is raised if the power fails to

the unit.

2 = Control

Relay is programmed as a control relay, which

will energise ON, and de-energise OFF.