5

1.4 Specifications:

- electrical parameters (tab.3)

- mechanical parameters (tab.4)

- operation safety (tab.5)

- operating parameters (tab.6)

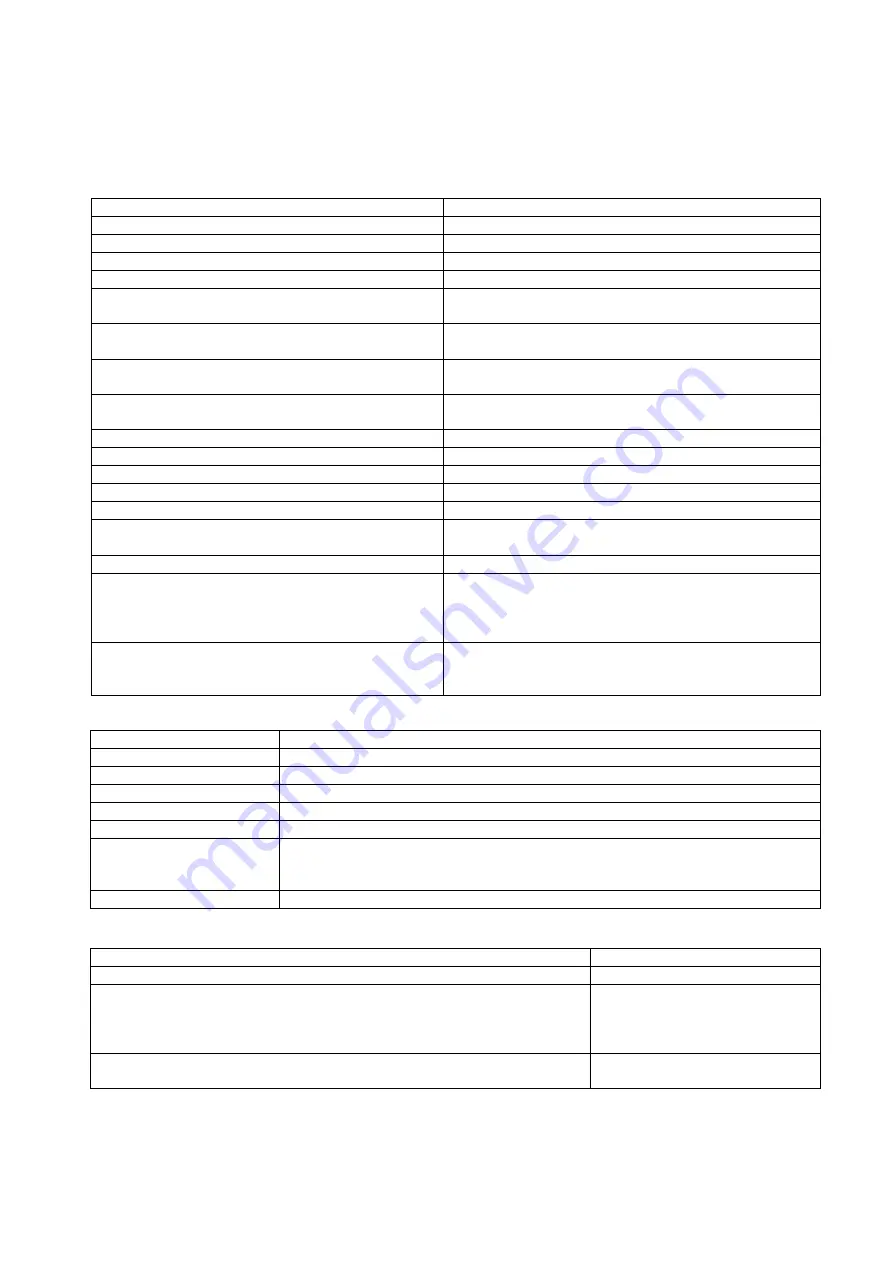

Electrical parameters (tab. 3).

Mains supply

176÷264V AC

Current up to

1.4A@230VAC

Power frequency

50÷60Hz

Supply power

155W max.

Efficiency

83%

Output voltage

27,6V DC – buffer operation

19V÷27,6V DC – battery-assisted operation

Output current

5A + 0,5A battery charge

3,5A + 2A battery charge

Output current t

AMB

<30°C

5 A + 0,5A battery charge - refer to chart 1

3,5 A + 2A battery charge - refer to chart 1

Output current t

AMB

=40°C

3,3 A + 0,5A battery charge - refer to chart 1

1,8 A + 2A battery charge - refer to chart 1

Voltage adjustment range

24÷28V DC

Ripple

150mV p-p max.

Battery charge current

0,5A/2A max. @ 2x 17Ah (± 5%)

Short-circuit protection SCP

electronic

Overload protection OLP

PTC polymer fuse

Overvoltage protection OVP

U>115% ÷ 150% of the output voltage (set), power

cut off, automatic return

Excessive discharge protection UVP

U<19 V (± 5%) – disconnect of connection battery

LED indication:

- AC diode indicating AC power status

- AUX diode indicating DC power status at

the PSU output

- red, normal status – on, failure: off

- green, normal status – on, failure: off

Technical outputs:

- TAMPER indicates enclosure opening

- microswitch, NC contacts (enclosure closed),

0,5A@50V DC (max.)

Mechanical parameters (tab. 4).

Enclosure dimensions

405 x 355 x 90+8 (400 x 350 x 90) (WxHxD)

Fixation

see figure 2

Fitting battery

2x 17Ah/12V (SLA) max.

Net/gross weight

3,70kg/ 4,0kg

Enclosure colour

RAL 9003

Closing

Cheese head screw x 1 (at the front), lock assembly possible

Connectors

Power-supply:

Φ

0,63-2,50 (AWG 22-10)

Outputs:

Φ

0,63-2,50 (AWG 22-10), battery output BAT: 6,3F-2,5

TAMPER output: wires

Notes

The enclosure does not adjoin the assembly surface so that cables can be led

Operation safety (tab.5).

Protection class PN-EN 60950-1:2007

I (first)

Protection grade PN-EN 60529: 2002 (U)

IP20

Electrical strength of insulation:

- between input and output circuits of the PSU (I/P-O/P)

- between input circuit and PE protection circuit (I/P-FG)

- between output circuit and PE protection circuit (O/P-FG)

3000 V/AC min.

1500 V/AC min.

500 V/AC min.

Insulation resistance:

- between input circuit and output or protection circuit

100 M

Ω

, 500V/DC