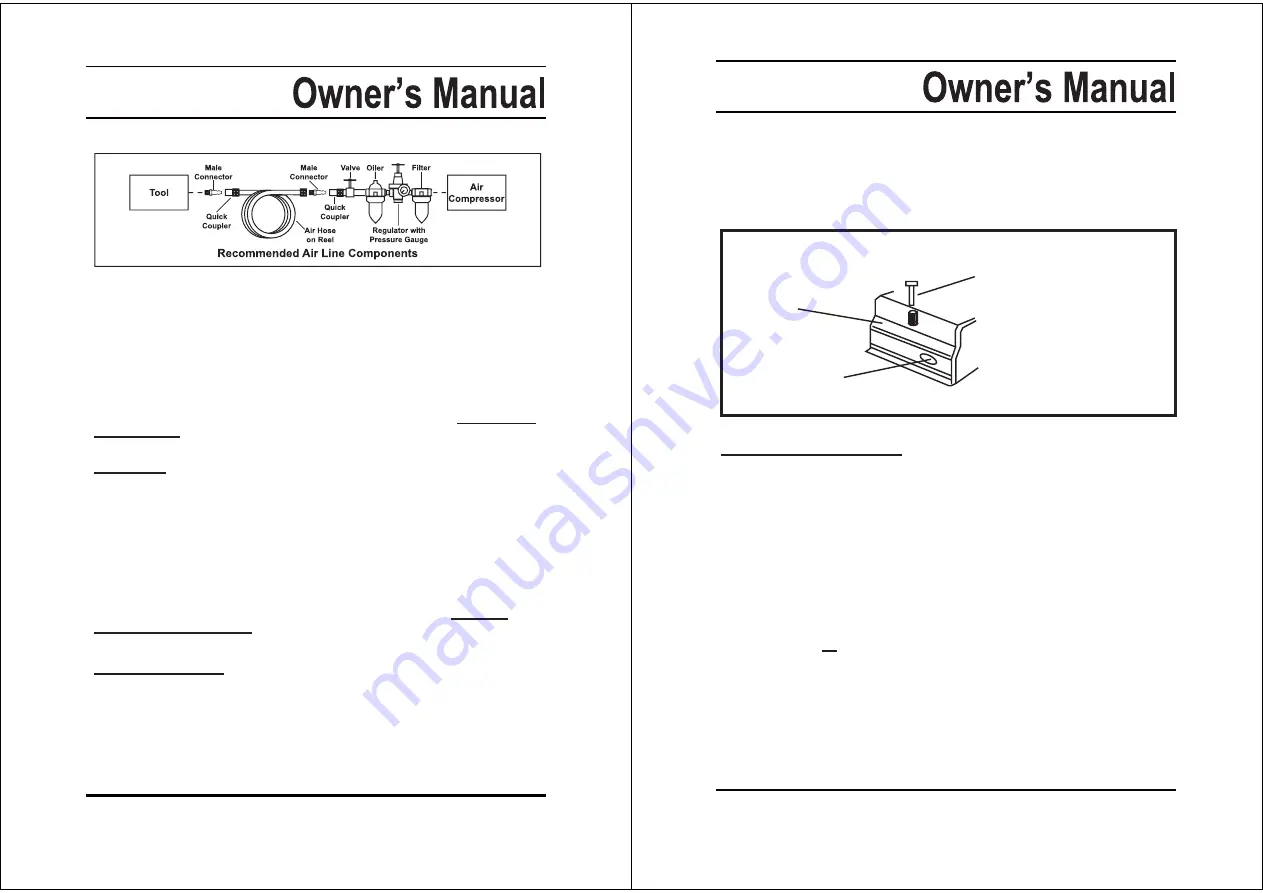

TO EXTEND THE LIFE OF YOUR AIR TOOLS AND EQUIPMENT,

it is recom-

PHQGHGWRLQVWDOODQRLOHUDQGZDWHU¿OWHULQVHULHVZLWKWKH $LU2XWSXW/LQHRIWKH

Air Compressor.

OPERATING INSTRUCTIONS

NOTE:

)RUDGGLWLRQDOUHIHUHQFHVWRWKHSDUWVOLVWHGEHOR

w

UHIHUWRWKH

Assembly

Diagrams on pages 9, and 10.

To Check The Oil Level:

1.

7KH2LO:LQGRZ%LVXVHGWRGHWHUPLQHLIRLOLVQHHGHG 7KHRLOOHYHOVKRXOG

DOZD\VEHDWWKHPD[LPXPOHYHOUHGOLQHRQWKH2LO:LQGRZ

(See Figure C,

and Assy. Diagram B.)

UNPACKING

:KHQXQSDFNLQJFKHFNWRPDNHVXUHDOOWKHSDUWVVKRZQRQWKH

Parts

Lists on

pages 9, and 10

DUHLQFOXGHG

IMPORTANT!

7KLVFRPSUHVVRULVVKLSSHGZLWKWKHRLO¿OOSOXJUHPRYHGDQGZLWKRXW

oil.

7KHRLO¿OOSOXJLVDWWDFKHGWRWKHSRZHUFRUGDVDUHPLQGHUWRDGGRLOWRWKH

FUDQNFDVH $GGRLOWRWKHSURSHUOHYHODVH[SODLQHGEHORZDQGVHFXUHWKHRLO¿OO

SOXJEHIRUHXVH

5

2.

If necessary, add a

premium quality, 30-weight, non-detergent compressor oil

into the Oil Fill Hole until the level of oil reaches the maximum level as indicated

on the Oil Window (20B). The optimal capacity of the oil reservoir is 30 ounces.

'RQRWRYHU¿OO

. Then thread the Breather Valve back into the Oil Fill Hole, being

careful not to strip the plastic threads.

(See Figure C, and Assy. Diagram B.)

To Turn The Air Compressor On:

1.

Check to make sure the Water Drain Valve (10A) is fully closed.

2.

Turn the Air Flow Valve (6A) to its “OFF” position.

3.

Connect the air hose (not provided) to the Air Flow Valve (6A) of the Air Com-

pressor. Then, connect the other end of the air hose to the pneumatic tool (not

provided) that is to be used.

4.

Note: Always plug the Power Cord of the Air Compressor into a 115 V~

electrical source (±10% maximum variation).

5.

Rotate the “ON/OFF” Power Switch (1A) to the horizontal position to turn the Air

Compressor

on

. (Rotate the “ON/OFF” Power Switch (1A) to the vertical position

to turn the Air Compressor

off

.)

6.

$OORZVXI¿FLHQWWLPHIRUWKH

Tank Pressure Gauge (4A) to indicate

80 PSI

before

using the Air Compressor.

7.

Turn the Air Flow Valve (6A) to its “ON” position to allow air to the pneumatic tool.

FIGURE C

Breather Valve (14B)

Oil Window (20B)

Front Cover (18B)

6