18

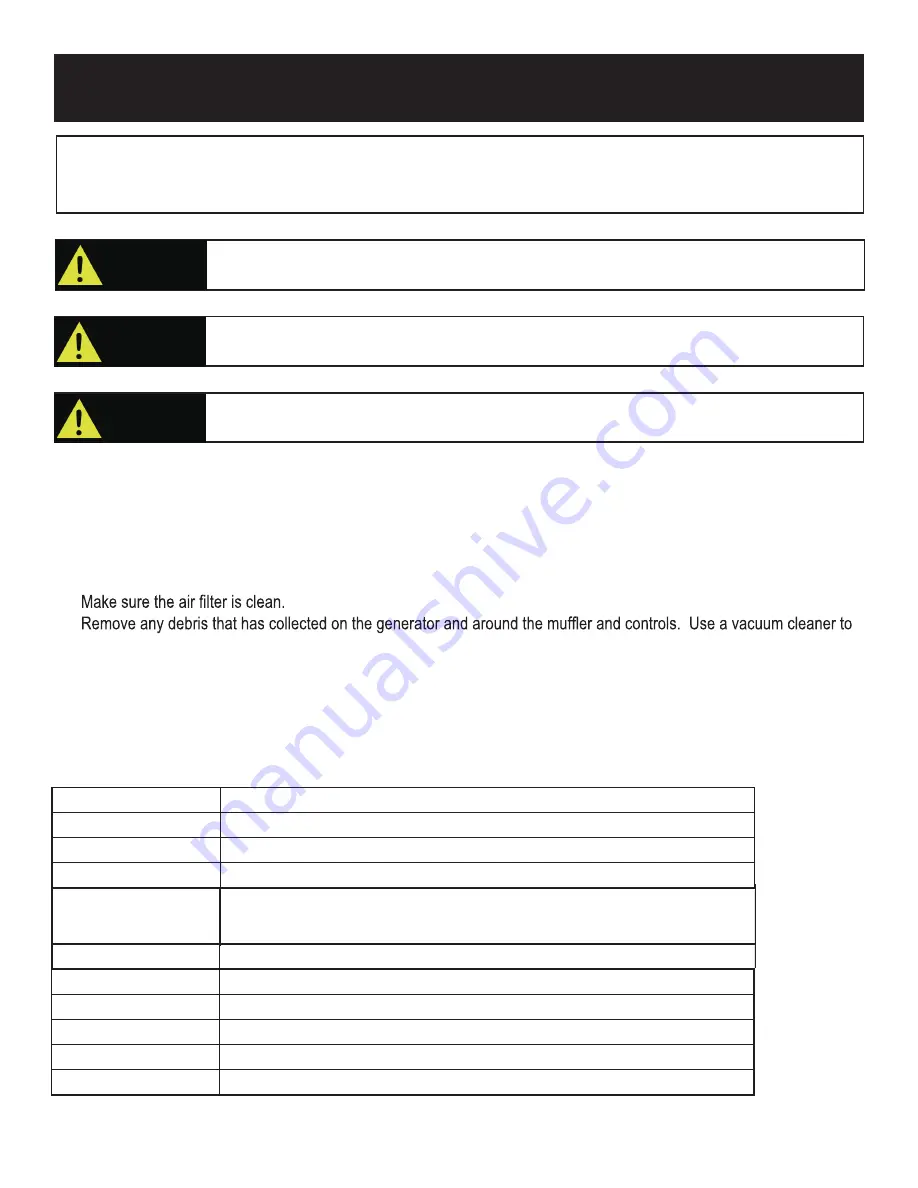

MAINTENANCE

Regular maintenance will extend the life of this generator and improve its performance. The warranty does not cover

items that result from operator negligence, misuse, or abuse. To receive full value from the warranty, operator must

maintain the generator as instructed in this manual, including proper storage.

Before inspecting or servicing this machine, make sure the engine is off and no parts are

moving. Disconnect the spark plug wire and move it away from the spark plug.

Pre-Operation Steps

Before starting the engine, perform the following pre-operation steps:

• Check the level of the engine oil and the fuel tank level. Check for any leakage.

• Check fuel hose for cracks or damage. Replace if necessary.

•

•

pick up loose debris. If dirt is caked on, use a soft bristle brush.

• Inspect the work area for hazards.

After Each Use

Follow the following procedure after each use:

• Shut off engine.

• Store unit in a clean and dry area.

WARNING!

Maintenance Schedule

If you are unsure of how to perform a maintenance task, have the unit serviced by a PU

LSAR

dealer

CAUTION!

CAUTION!

Only use specified PULSAR replacement parts

.

After First 5 Hours

Change Oil

After 8 Hours or Daily

Clean Debris from Generator and Air Filter area

Check Engine Oil Level

Annually (25 hr Use)

Check and Clean Air Cleaner

Inspect

Muffler and Spark Arrester

Annually (100 hr Use)

Service Spark Plug

Inspect Fuel Valve and Fuel Lines for leaks or damage

Inspect Muffler and Spark Arrester

Check and Clean Air Cleaner Assembly, Replace Air

Filter

Clean Cooling System Cylinder Head Fins and Flywheel Fan

Change Engine Oil after the first 25 hours, again at 50 hours; then every 100

hours thereafter

.