19

Checking Spark Plug

• Remove the Engine Service Panel to gain access to the spark plug.

• Disconnect the spark plug wire from the spark plug.

• Before removing the spark plug, clean the area around its base to prevent debris from

entering the engine.

• Insert a 19mm, 6-point, deep-well spark plug socket wrench through the opening on

the outside of the cover. Turn the wrench counter clockwise to loosen and remove

spark plug.

• Check for discoloration and clean carbon deposits from the electrode with a wire

brush.

• Check the electrode gap and slowly adjust to 0.6 - 0.7mm (0.024-0.028 in) if

necessary.

• Reinstall spark plug and tighten to 20.0Nm (15 ft-lb) of torque.

• If spark plug is worn, replace only with an equivalent type. Spark plug should be

replaced annually regardless of apparent condition

.

• Reconnect spark plug wire, firmly, until it clicks into place.

Standard Spark Plug:

F7TC/F7RTC

Spark Plug Gap:

0.6 - 0.7mm (0.024-0.028 in)

Spark Plug Torque:

20.0Nm (15 ft-lb)

MAINTENANCE

Carburetor Adjustment

The carburetor is low emission and is equipped with a non-adjustable idle mixture valve. If adjustment is needed

contact an authorized PULSAR Products dealer.

Oil Recommendations

•

•

Do not use special additives.

Outdoor temperatures determine the proper oil viscosity for the engine. Use the chart

to select the best

viscosity for the outdoor temperature range expected.

-22

-4

14

32

50

68

86

104

-30

-20

-10

0

10

20

30

40

SA

E 3

0

10

W

-3

0

Sy

nt

he

tic 5

W

-3

0

0

W-30

*

**

C

F

Check oil level more frequently

Note:

*

*

(4

C

) the use of SAE 30

Below 40

F

*

will result in hard starting.

Above 80

F

(27

C

) the use of 10W-30

may cause increased oil consumption.

0.6-0.7mm

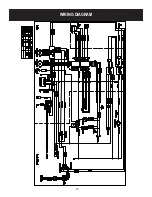

Summary of Contents for PG4500BiSRCO

Page 25: ...WIRING DIAGRAM 25 M θ θ ...