9

Operation

Adding Gas and Oil

□

□

Remove gas cap. Place funnel securely and add fuel.

Do not top off.

Secure the gas cap and wipe off any excess fuel.

See Figure 1-6.

□

□

□

Place the tiller on a level surface.

Remove the filler cap. Place the funnel securely and add oil.

Do not top off. Check dipstick to confirm adequate amount

of oil.

Secure the oil cap and wipe off any excess oil.

See Figure 1-9.

□

□

□

We recommend the use of 10W-30 oil. Other high-quality

detergent oils are acceptable if classified for service SF, SG,

SH. SJ or higher.

Do not use special additives.

Outdoor temperatures determine the proper oil viscosity for

the engine. Use the chart to select the best

viscosity for the outdoor temperature range expected.

1

WARNING:

Use extreme care when handling gasoline.

Gasoline is extremely flammable and the vapors are

explosive. Never fuel the machine indoors or while the

engine is hot or running. Extinguish cigarettes, cigars,

pipes and any other sources of ignition.

IMPORTANT:

Use only Regular Octane Fuel.

IMPORTANT:

We recommend using 10W-30 Oil.

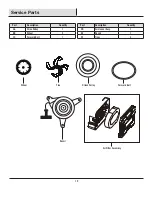

Figure 1-6

Figure 1-7

104

86

68

50

32

14

-4

-22

40

30

20

10

0

-10

-20

-30

°C

°F

SAE 30

10W-30

SYNTHETIC 5W-30

5W-30

GAS

OIL