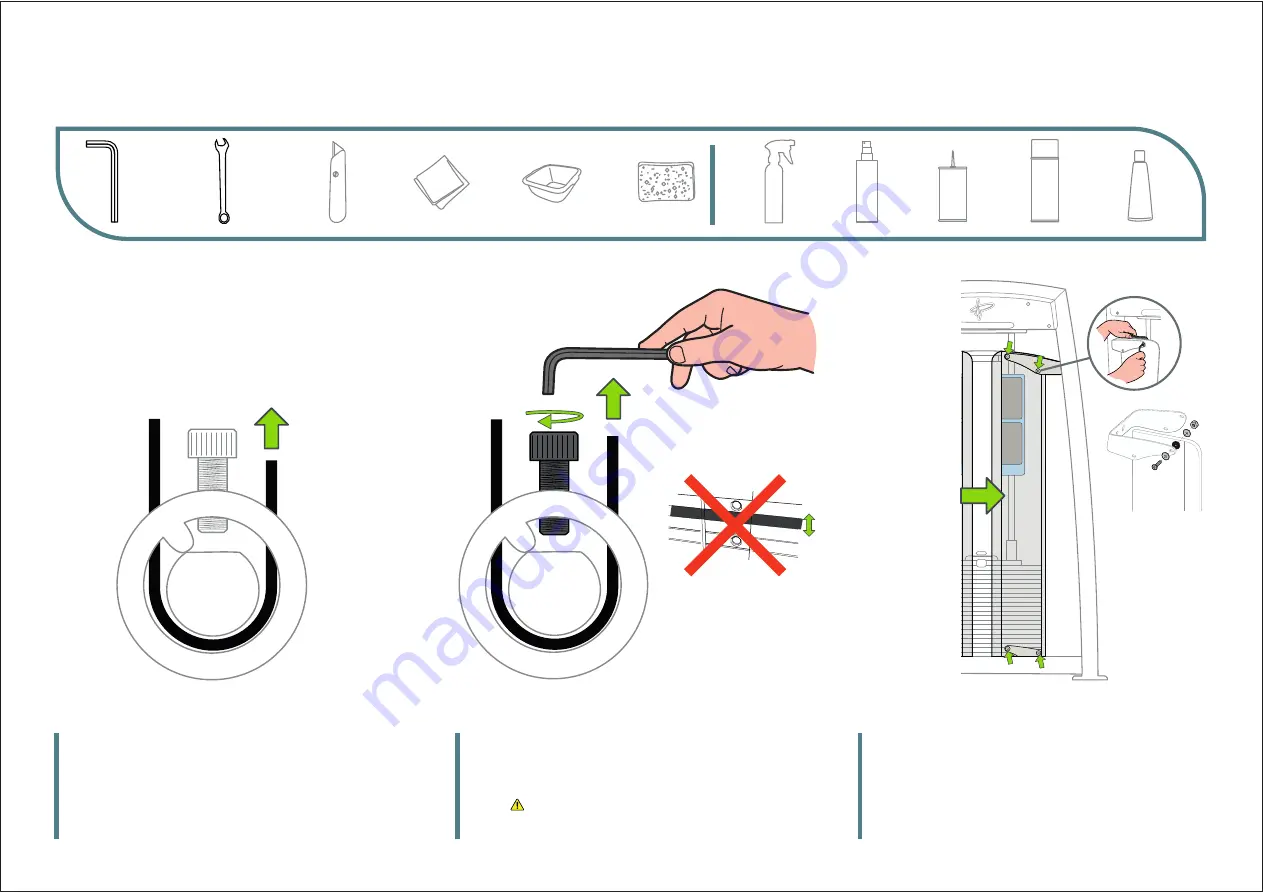

Pull the short end of the belt to

remove slack.

Slide acrylic panel into place behind

the brackets and secure into place

with nuts and bolts ensuring that it is

aligned with rear panel and replace

weight stack pin.

12

Too much tension

on belt will lift top

weight resulting in

weight stack

misalignment.

1x10mm

1x6mm

1x4mm

4.1 Tensioning belt from weight stack clamp

Tighten both cap screws as tight as

possible using a long arm allen key

while still pulling on loose end of belt.

SAFETY NOTE: Torque tighten to

17 N.m (145 lbf.in)

Summary of Contents for EVOLVE

Page 1: ...TM E V O L V E MAINTENANCE ...

Page 26: ...User notes ...

Page 27: ...User notes ...

Page 28: ...User notes ...

Page 29: ...User notes ...