Summary of Contents for Strength

Page 1: ...Strength Installation Maintenance Safety Reference Parts Manual EU US ...

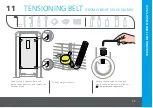

Page 31: ......

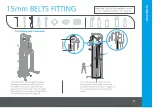

Page 32: ......

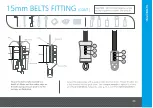

Page 33: ......

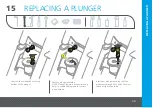

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 48: ...48 USER NOTES 21 USER NOTES ...

Page 49: ...49 USER NOTES USER NOTES CONT ...