ALTEC AIR, LLC

P1500W Series Air Dryers User’s Guide

Page 88 of 100

P011787 – Rev. S

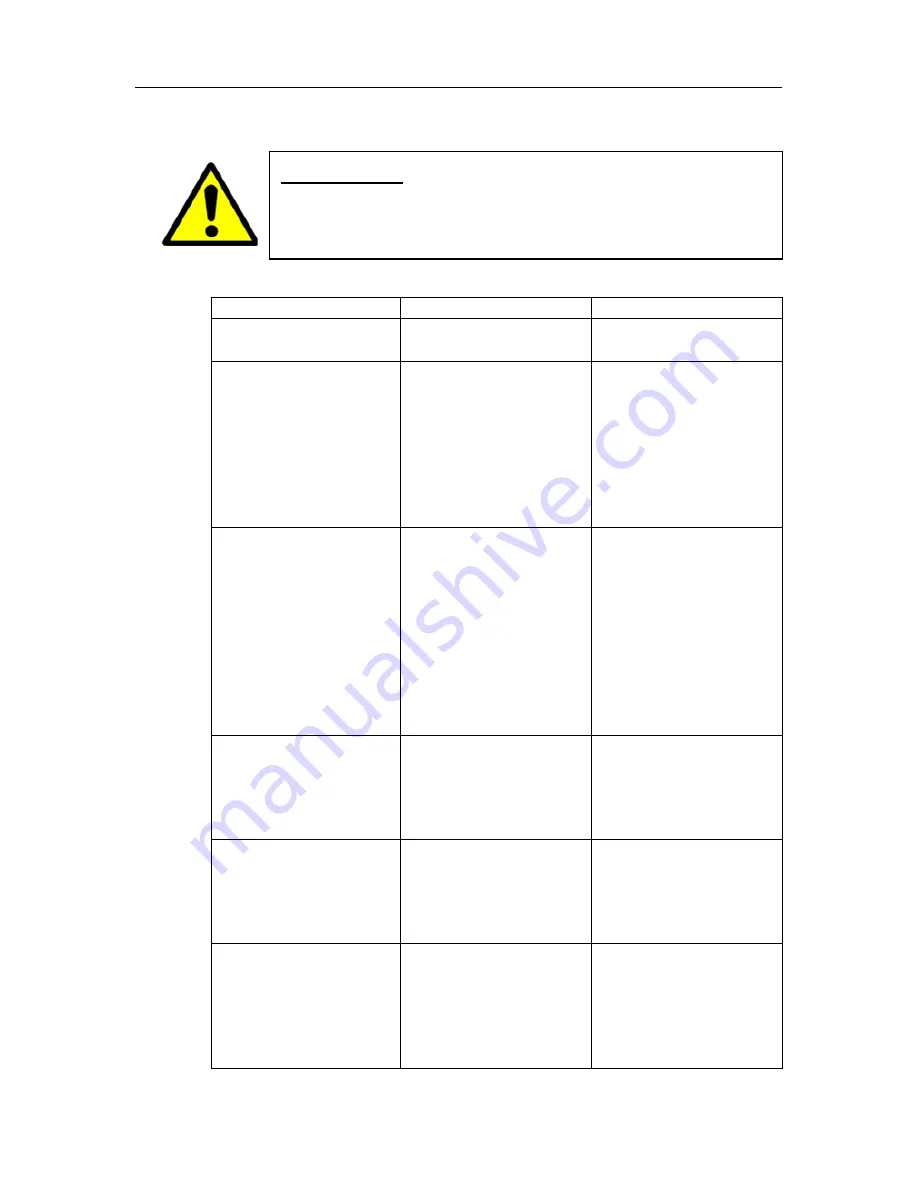

13.9 High Humidity

Possible Cause

Check

Corrective Action

Low System Pressure

Verify System Pressure

Adjust System Pressure.

Low Flow Rate

Verify Flow Rate

(

FLOW

) reading is low

Install the included

Precision Bleed Orifice

fitting to maintain a

constant air flow.

Raise capacity control

setting to 90 PSI.

(section 6.5.13)

High Humidity Alarm

set point too low

Verify High Humidity

Alarm set point

If Flow Rate is low,

allowing a higher alarm

set point (up to 10%)

will allow dryer to run

within acceptable

levels.

Raise High Humidity

Alarm set point

Over 10% not

recommended

Defective Humidity

Sensor

Perform the Testing

Humidity Alarm and

System Shutdown test

(section 9.13 )

Troubleshoot

Can’t

Create a High Humidity

Alarm / Shutdown

condition

(section 13.10 )

Heatless Dryer not

cycling between towers

Verify consistent

Heatless Dryer cycling

(section 9.6 )

Troubleshoot

Inconsistent Heatless

Dryer Cycling

condition

(section 13.13 )

Defective Control

Board

Unplug Humidity

Sensor from Control

Board (see section 11.1

for Board location)

Humidity reading

should drop to 0%

If Humidity did not

drop to 0%, replace

Control Board (section

11.2 )

CAUTION!

Do not test the Humidity Sensor with an ohm meter or apply

any DC voltage.

This will render the Humidity Sensor defective.

Summary of Contents for P1500W Series

Page 2: ......