PUREGAS, LLC

P1500W2 Series Air Dryers User’s Guide

Page 47 of 100

P012253 – Rev. H

8.15.2

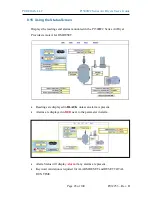

Resetting Compressor Total Run Time

8.15.2.1

Click on the

RESET TOTAL RUN TIME

Button to remotely reset

Compressor Total Run Time displayed on Status Screen.

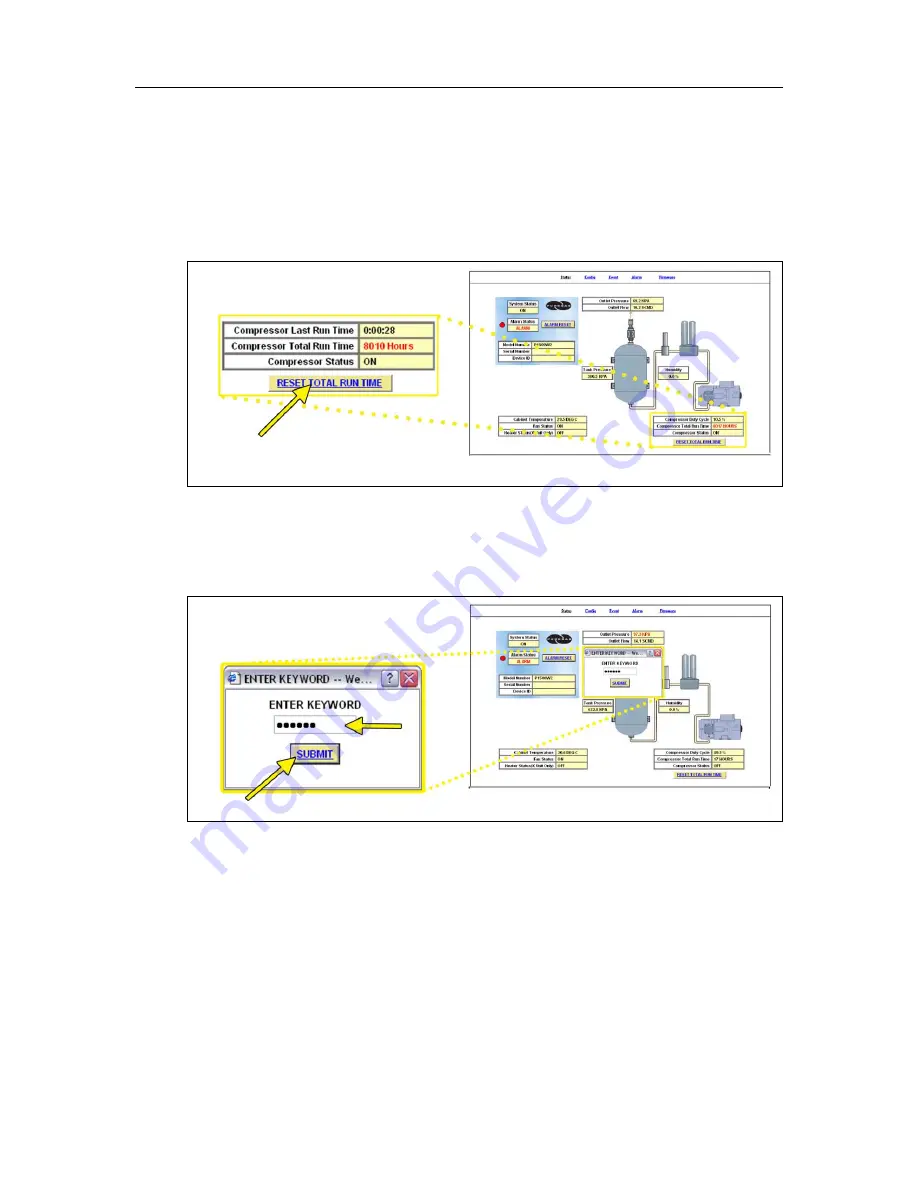

8.15.2.2

Enter Keyword (default is 123456)

8.15.2.3

Click on

SUBMIT

Button when done.

Summary of Contents for P1500W2

Page 2: ......